you're currently reading the news digest published from 16 Mar 2020 to 23 Mar 2020

featured5

of-interest1

video1

press13

featured

Coping with COVID | Adjusting to maintain progress

COVID-19 needs no introduction. But for a 35-country collaboration like ITER, the dramatic worldwide spread of the virus has introduced an entirely new set of challenges for international project management. Whether the task at hand is talent recruitment, efficient financial and procurement processes, ongoing fabrication of components, preparation of the Tokamak Building for the Assembly Phase, or monitoring and receiving shipments of giant superconductor magnets, each member of the ITER team, from senior management to staff and collaborators, has tried his/her best to respond with the necessary adjustments, putting safety first as always. From the beginning of the new coronavirus outbreak, ITER has taken all precautionary measures recommended by the World Health Organization and by the French government as the ITER Host State to preserve the health of all the stakeholders to the project. Given that China and Italy, the two most affected ITER parties so far, are both countries with intensive manufacturing of ITER components, the ITER Organization in France was in constant contact and, to some extent, was able to learn from their early experience with combating COVID-19. At all times, project-wide, the core focus has been to ensure the safety and wellbeing of ITER staff and collaborators, while maintaining progress on critical activities to the extent possible. Translated, this has meant emphasizing individual responsibility to follow all hygiene measures, project-wide solidarity as a single One-ITER team, advanced planning for multiple scenarios, and clear guidance from ITER Council Chair and ITER Organization top management at every level as the situation has evolved. ITER has been fortunate that, as of this publication, no one at the ITER site has been tested positive or been hospitalized for COVID-19. We hope this situation will be preserved, even as we are aware that this of course could change at any time. Teleworking operations were tested well in advance, and have been implemented massively. Digital communication and meetings have become the new norm. On the worksite, critical operations have been successfully maintained so far. In addition to essential safety and security staff and maintaining life-cycle operations such as electricity and water supply, this has included: completion of resin injection into poloidal field coil #5 (PF5) under the oversight of the European Domestic Agency, Fusion For Energy; completion of the cryostat upper cylinder by the Indian Domestic Agency, with preparations underway to place it in storage; and continued finalization of the Tokamak Building to be turned over from Fusion for Energy to the ITER Organization at the end of March. Critically, it also includes preparations to receive three of the giant superconductor magnets: toroidal field coil #9 (TF9), which arrived at the Marseille port from Italy one week ago; toroidal field coil #12 (TF12), scheduled to arrive in Marseille from Japan in about ten days; and poloidal field coil #6 (PF6), which has been packaged for shipment and should depart China in the next few days. Newsline will continue to cover the progress that our home and international teams are achieving, despite the difficult global context, and we will keep our readers abreast of any developments in our organizational response measures.

Deliveries | A third magnet ready for transport to ITER

Three ITER magnets are now in transit to ITER from different points on the globe—two toroidal field magnets and one poloidal field coil. In terms of component weight, without counting packaging and transport frames, they represent more than 1,000 tonnes of equipment. On Sunday 22 March, a 400-tonne ITER magnet—poloidal field coil #6 (PF6)—left the premises of the Institute of Plasma Physics, Chinese Academy of Sciences (ASIPP) in Hefei, China. The first in the poloidal field magnet series to be installed into the Tokamak Pit at ITER, PF6, is the result of collaboration between the procuring Domestic Agency—Europe's Fusion for Energy—and the ASIPP as principal contractor. After a manufacturing completion ceremony in September 2019, the magnet went through extensive testing before being packaged for transport. When it arrives at ITER along the dedicated road itinerary, which had to be adapted to its imposing dimensions, it will be delivered to Europe's on-site winding facility, where Fusion for Energy teams will perform final acceptance tests, as well as further electrical, leak and cold tests. Only then will the component be ready for handling and transport to the Cleaning Facility and finally the Assembly Hall, where overhead cranes will take charge of the load for delivery to the Tokamak Pit.

Heaviest load yet | Europe's coil soon to hit the road

It's big, it's heavy, it's precious and it's highly symbolic: the toroidal field coil that was unloaded at Marseille industrial harbour on 17 March is the most massive, most sophisticated ITER component to arrive in France, and the first to belong to the very core of the ITER Tokamak. Procured by Europe and finalized in Italy, the coil is part of a set of 19 needed by the ITER machine (18 plus one spare). It is a unique piece of high technology: twelve years of work, involving more than 700 people and 40 different companies went into its making. Ensuring safe delivery to the ITER site has come with many daunting challenges. Global logistics provider DAHER, the ITER Organization, and the European Domestic Agency Fusion for Energy collaborated closely for three years to establish procedures and to design and manufacture lifting tools and a transport frame. The resulting transport and storage frame, a 100-tonne structure that brings the total load to 420 tonnes, is in itself a remarkable achievement. Not only does it protect the component throughout the many handling, transfer and transport operations, it is also designed to allow access for assembly teams during the preparation phase prior to the component's transfer to the on-site Assembly Hall. The last leg of the journey will begin on 23 March with the crossing of the inland sea Étang-de-Berre, followed by four nights of travel along the ITER Itinerary. Due to the highly unique nature and sheer bulk of the component, progression along the Itinerary will be slower than with previous highly exceptional loads. At the break of day on 3 April, the convoy will arrive at ITER—a major event in the history of the project. It will soon be followed by the arrival of a toroidal field coil from Japan, a vacuum vessel sector from Korea, and a poloidal field coil manufactured in China for Europe.

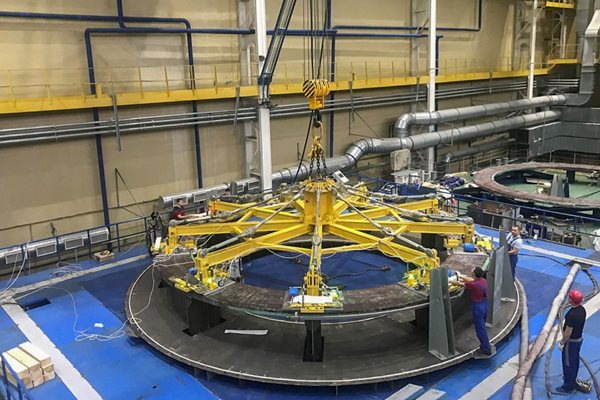

Russia's ring coil | Entering the final sequence

The smallest of ITER's poloidal field coils is entering the final sequence in a long series of activities that transform cable-in-conduit superconductor into a completed magnet ready for shipment to ITER. After successful winding, impregnation and joint assembly phases, the eight resin-hardened double pancakes of poloidal field coil #1 (PF1) are ready for stacking at the Sredne-Nevsky shipyard in Saint Petersburg. Situated on the Neva River, the shipyard enjoys direct access to the Baltic Sea and global shipping routes. One by one, the double pancakes will be transported by overhead crane and assembled on the multi-stage assembly platform for PF1 coil fabrication that has been erected atop a stationary barge. At the end of the manufacturing process, the barge will be pulled backward out of the construction hall and into the river. There the coil and its platform will be transferred to a ship to begin the journey to ITER. During the final fabrication steps this year, the stacked double pancakes will be joined electrically, a second vacuum impregnation will be performed to harden the overall assembly, and additional components such as clamps, protection covers, and pipes will be added. The PF1 magnet is the smallest of ITER's six poloidal field coils, which are installed outside of the toroidal field magnet structure to shape the plasma and contribute to its stability by keeping it away from the walls. The manufacture of a poloidal field coil, nine meters in diameter and weighing 190 tonnes, has been a ten-year undertaking, from the time the original Procurement Arrangement was signed with the ITER Organization, to the moment the coil leaves the factory for ITER (schedule in the first quarter of 2021). The most important technologies for the fabrication of PF1 were developed at the Efremov Institute (JSC "NIIEFA"), which also designed, manufactured and tested a large part of the equipment.

United States | A roadmap to fusion energy

Hundreds of scientists across the United States—representing a broad range of national labs, universities, and private ventures—have collaborated to produce A Community Plan for Fusion Energy and Discovery Plasma Sciences, released this month. It offers a consensus view of the bold steps to take nationally to deliver fusion energy and advance plasma science. The community-driven strategic plan—the fruit of a 15-month collaborative effort—is designed to help the Fusion Energy Sciences Advisory Committee (FESAC) fulfil a US Department of Energy (DOE) charge for the development of a long-range strategy for the DOE Fusion Energy Sciences program. The charge, dated 30 November 2018, requested the American Physical Society's Division of Plasma Physics (DPP) to begin by surveying the scientific community broadly; this was executed through group discussions, webinars, town halls, focus groups, and dedicated workshops initiated by the DPP's Community Planning Process (documented here). Now, in a second phase, a FESAC subcommittee will use the input from the Community Plan to develop a long-term plan to submit to the US DOE by December 2020. The 200-page Community Plan for Fusion Energy and Discovery Plasma Sciences reflects the strong sentiment within the community that future research in the areas of fusion science and plasma physics should be driven by the goal of constructing fusion pilot plant on US soil. In this, and in the report's recommendation to remain a partner in ITER in order to fully reap the benefit of participation in the world's first burning plasma experiment, the recommendations in the Community Plan are broadly consistent with the National Academies Burning Plasma report published in late 2018. The report establishes a set of milestones that the US fusion community has agreed should be pursued in its effort to create practical fusion energy: Start immediately on the pre-conceptual design for a new US tokamak facility for operation by the end of the decade; Develop a shared neutron source facility for research on fusion materials; Maintain participation in the international ITER program and expand public-private collaboration in the United States to accelerate research in fusion materials and technology; Leverage advanced computing technologies for better understanding and modelling; Embrace innovation in developing solutions to well-known fusion challenges. As ITER Director-General Bernard Bigot observes: "For every ITER Member, getting the highest return on investment from the ITER Project in its future operational phase requires having a corresponding well-structured domestic program. It is deeply gratifying to see the results of this community-based multi-sector effort in the US, as a substantial step toward establishing a robust US fusion program." A Community Plan for Fusion Energy and Discovery Plasma Sciences can be downloaded here. Read reports by General Atomics (home to the DIII-D tokamak), the MIT Plasma Science and Fusion Center (home to the former Alcator C-Mod tokamak and promoter of SPARC, a compact, high-field, net fusion energy experiment), and the Princeton Plasma Physics Laboratory (home to the NSTX-U tokamak).

of-interest

Upgrade at Wendelstein 7-X

The Wendelstein 7-X stellarator facility at the Max Planck Institute for Plasma Physics (IPP) in Greifswald, Germany, is preparing for higher heating power and longer plasma pulses. After a successful campaign that ended in late 2018—during which operators were able to achieve discharge times of up to 100 seconds (2 MW of input heating power) or 30 seconds at 6 MW—the Wendelstein 7-X team is now preparing to install actively water-cooled components inside the vacuum vessel that will allow the next round of experiments to generate plasma pulses of up to 30 minutes. The previous cladding made of carbon tiles has now been removed, and the vessel is ready for the installation of the new water-cooled protective elements. Chief among them is the new divertor, a highly technical component made of plasma-facing front tiles mounted on water-cooled back plates—assemblies made of nearly 500,000 parts, which were the object of more than 15 years of development, fabrication and testing. Commissioning of the upgraded facility is expected to begin early next year. Read the full article on the IPP Greifswald website. --Cooling elements on the back side of a divertor plate. Photo: IPP, Michael Herdlein