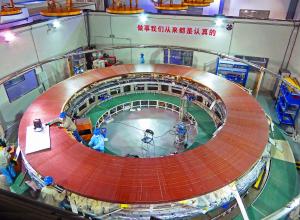

At the Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP) in Hefei, China, an 80-person team is involved in the fabrication of poloidal field coil #6 (PF6) on behalf of the European Domestic Agency*.

Each poloidal field coil is unique. Depending on the number of double pancakes (the building block of the coil) stacked to form the final assembly and the number of "turns" in each layer, ITER's poloidal field coils vary in weight from 193 tonnes (PF1) to 396 tonnes (PF6), and in diameter from 9 metres (PF1) to 24 metres (PF3 and PF4).

The sixth coil is the only one of the poloidal field set with nine double pancakes, compared to six or eight for the others. It also has double the number of spiral-like turns of the similar-sized PF1—meaning that more conductor is required. Finally, the clamp arrangement for the assembled PF6 coil will be heavier than the others due to an exceptionally thick bottom plate.

By September of this year, the contractor expects to have completed the fabrication process for the nine double pancakes—including winding, impregnation, and the creation of helium and electrical joints.

This will open the way to final assembly activities on the 10-metre-in-diameter coil, such as stacking, joining, ground insulation and final impregnation.

Please see the full report on the European Domestic Agency website.

*The second-smallest ring magnet for ITER is being fabricated in China on the basis of an agreement concluded with the European Domestic Agency.