L'énergie de fusion

La fusion—la réaction nucléaire qui se produit au cœur du Soleil et des étoiles—porte en elle la promesse d’une énergie durable et non émettrice de gaz à effet de serre. La maîtrise de cette source d’énergie constitue l’objectif d’ITER—l’installation expérimentale à mi-chemin des machines vouées à la recherche et des futures centrales de fusion.

Youtube est désactivé. Autoriser le dépôt de cookies pour accéder au contenu.

Le chemin des étoiles

L’objectif d’ITER est de produire une puissance de fusion équivalente à celle d’une centrale industrielle, d’ouvrir de nouvelles perspectives scientifiques et de mettre en œuvre l’ensemble des technologies requises par un réacteur de fusion industriel.

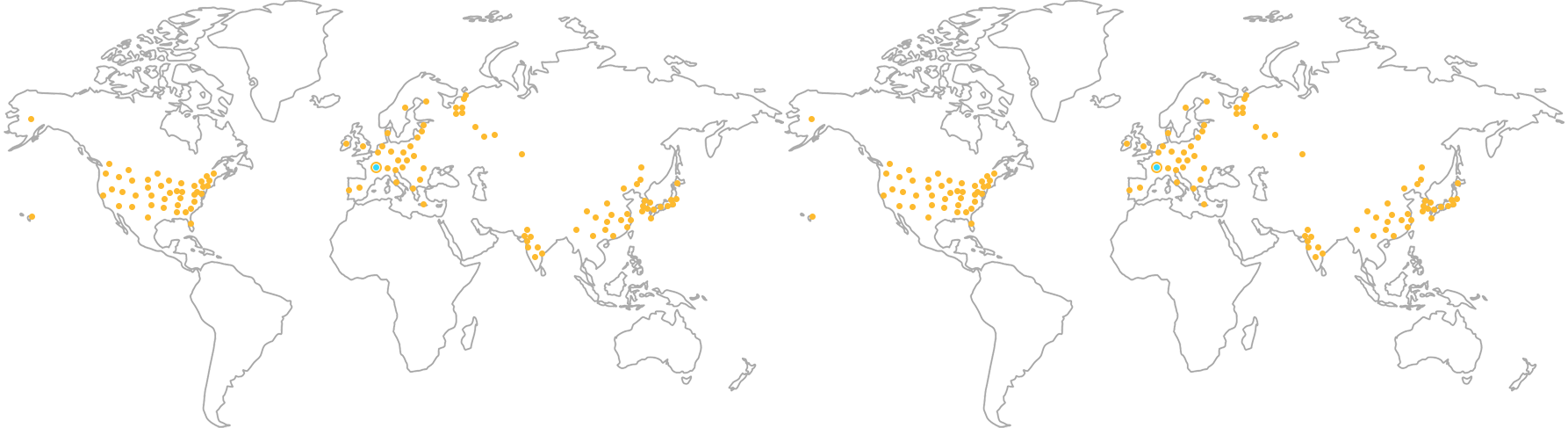

Ensemble… pour l’avenir

La Chine, l’Union européenne, l’Inde, le Japon, la Corée, la Russie et les Etats-Unis sont les pays membres engagés dans la construction, l’exploitation de l’installation ITER et la formation des scientifiques, des ingénieurs et des opérateurs des futures centrales de fusion.

Aux limites de la faisabilité

Repoussant les limites de la faisabilité technologique et industrielle, le tokamak ITER est la plus puissante des machines de fusion jamais conçues—une petite étoile née du génie humain.