The coconut factor

Cryopumps are highly sophisticated devices whose performance depends on the quality of a simple, natural product—coconut charcoal.

In ITER, cryopumps are responsible for creating the very high level of vacuum required inside the plasma chamber and surrounding cryostat. They work by condensing gas molecules on very cold surfaces.

Decades ago, when the cryopumps were under development, researchers determined that the material with the greatest capacity to capture gas molecules when cooled to cryogenic temperature—a process called “adsorption”— was finely ground charcoal from coconut husks.

The unique quality of coconut charcoal lies in the exceptionally large internal surface developed by the walls of its pores (no less than 1,200 square metres per gram of charcoal!) that allows for the efficient capture of helium ash from the fusion reaction.

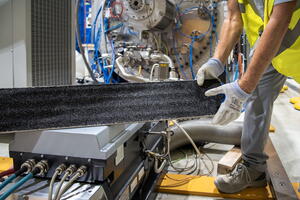

Robert Pearce, who has been involved in cryopump design and manufacturing for more than three decades; Alessandra Iannetti, who manages the cryopump test facility, and Vacuum & Cryogenics Engineer Atlantis Cobalt are seen in the photo above holding a cryopump panel, coated on both sides with coconut charcoal.

There are 28 such panels in each of the six torus cryopumps, which amounts to approximately 7 kg of ground charcoal per pump.