Creative solutions implemented on site

How to replace critical cooling circuits on thermal shield panels that are hard to access or too large to easily transport off site?

As part of the ongoing project to replace the cooling piping on ITER’s vital thermal shield system, two crucial repair initiatives are underway on site.

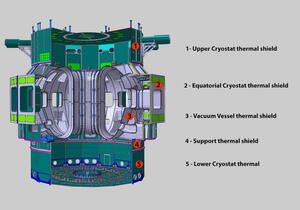

The role of the ITER thermal shield is to block thermal loads from being transferred from warm components to the superconducting coils and other structures operating at cryogenic temperatures. One layer is installed between the vacuum vessel and the superconducting magnets (the vacuum vessel thermal shield); another is installed between the magnets and the cryostat (the cryostat thermal shield).

After microscopic cracks were discovered in the piping of three elements of the vacuum vessel thermal shield in 2021, the decision was made to replace all the cooling pipes on the vast thermal shield system. While the repair of the vacuum vessel thermal shield, as well as some other thermal shield elements, is underway at the INOX-CVA facility in Vadodara, India, two crucial sets of pipe replacements on the 530-tonne cryostat thermal shield system are being handled on site at ITER, a choice that was made to overcome specific constraints.

For the 18 main panels that form the equatorial cryostat thermal shield cylinder (see #2 on the diagram), the size of the panels—each one measuring approximately 5 x 7 metres and weighing 4 tonnes—means they would be classified as a “highly exceptional load” and complex logistics would be required to ship them to India. Instead, space was found in the former poloidal field coil winding facility for on-site repair.

The repair project, which began in January 2026 and should be completed by the first quarter of 2027, requires the existing pipes to be removed and the areas where the pipes were attached to be buffed to ensure there are no remaining corrosive residues and that the stringent requirements for low surface roughness are achieved to preserve low emissivity. Then, the new pipes will be attached in a pattern that avoids fragilities associated with double welding in the same location.

“It was a complex project to do 3D modelling for an entirely new design that re-routes the pipes while providing the same level of cooling and having them arrive at the same interfaces to the main cooling network,” says Patrick Petit, the ITER Project Leader overseeing the repairs.

For the lower cryostat thermal shield cylinder (see #5 on the diagram), repair has to be carried out directly in the tokamak pit because the component cannot be moved from its installed position. Due to cleanliness constraints, work such as cutting, buffing, and welding must be kept to a minimum; as a result, the old piping system will be left in place and a new system of piping will be attached alongside it. To avoid excessive welding, the new cooling pipes will be bolted in place with copper thermal straps that are optimal for conducting the cold generated by the helium cooling fluids in the pipes to the thermal shield.

“The main challenges with the lower cryostat are cleanliness and also access, because the work is being done in a very restricted space,” says Guillaume Vitupier, the contract responsible officer for both the equatorial cryostat thermal shield and lower cryostat thermal shield cylinder repairs.

Because parts of the lower cryostat thermal shield cylinder are currently blocked by the temporary position of poloidal field coil #5, the repairs are being done in two batches. The first batch will be completed by the end of 2026 and the second is scheduled for 2028, when poloidal coil #5 is moved to its final position and the rest of the lower cryostat becomes accessible. Both on-site pipe repair projects are being carried out by the Indian company INOX.