New fusion material tested on nanoscale

13 Jan 2012

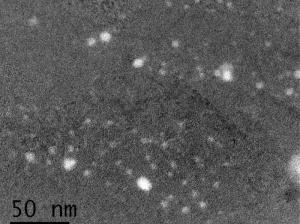

The image shows disperse yttrium oxide (Y2O3) nanoparticles in ODS/Fe12Cr steel. Copyright: Universidad Carlos III de Madrid.

The success of the fusion endeavor will crucially depend on the development of new materials capable of withstanding the harsh conditions inside a fusion reactor. The high temperature resulting from the fusion reactions together with neutron fluences of up to 200 displacements per atom (dpa) during the estimated lifetime of a reactor could give rise to hardening, swelling and microstructural changes and could thus significantly degrade the structural components of a fusion device.

Reduced activation ferrite steels strengthened by a dispersion of oxide nanoparticles are considered viable candidates for fusion applications. However, the microstructural stability and mechanical behavior of these steels when subjected to the aggressive operating conditions for an extended period of time is so far uncertain. That is why scientists at Universidad Carlos III de Madrid (UC3M), Oxford University (United Kingdom) and the University of Michigan (USA) have now joined their efforts in order to better understand the steels' atomic scale evolution under high temperature and irradiation conditions. "Until recently, studies on the microstructure of these steels have been on a micrometric scale," says Vanessa de Castro from Madrid University's Physics Department. "However, the nanometric scale is more relevant in understanding the phenomena that occur under irradiation."

In a recent paper published in Materials Science and Technology the consortium reports about the first results after having added nanometric particles to the steels which seem to help improve the mechanical properties and increase the steel's resistance.