Hands-on remote handling

25 Jan 2012

The European Domestic Agency F4E has signed a contract to receive engineering support over the next four years in the field of remote handling with OTL, Assystem UK and CCFE for a budget in the range of EUR 3.5 million.

Mechanical, electrical, electronic and control systems engineering linked to remote handling systems and components will be covered by the contract.

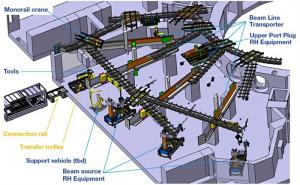

The work will be structured along the four packages for which Europe is responsible in this area: the divertor remote handling system; the cask and plug remote handling system; the in-vessel viewing system; and the neutral beam remote handling system. Furthermore, the framework contract could be used to verify the remote handling compatibility of other ITER systems like plugs and in-vessel components.

The scope of the contract is to support design and fabrication studies of remote handling equipment and respective systems; industrial evaluation of remote handling concepts and solutions in the areas of remote maintenance and decontamination; radiation tolerance assessments of components and materials; and the review of CAD models, technical specifications and safety evaluations.

The knowledge gained from the contract is expected to be complemented by existing and future grants in the area of remote handling when needed.

When ITER begins operating, inspections or repair of any of the tokamak components in the activated areas will be conducted by remote handling. Cutting-edge technology underpinned by precision and reliability will be necessary to manipulate and replace components weighing up to 50 tonnes.