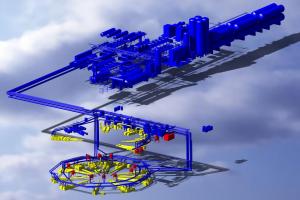

ITER's cryolines to enter prototyping phase

On 30 January this year the Procurement Arrangement for the delivery of the cryolines system was signed by the Indian Domestic Agency with the ITER Organization. ITER India has complete responsibility for the procurement, installation and performance of cold acceptance tests for the ITER cryolines.