Designing an antenna the size of a bus

1 Jun 2012

-

Sabina Griffith

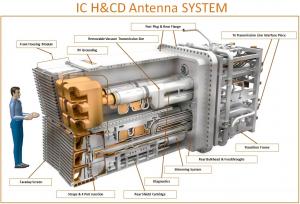

One of the two impressive ICRF antenna systems that will deliver 10 MW of heating power each into the ITER machine.

The ion cyclotron resonance heating (ICRH) system, one out of three heating systems installed in ITER, will deliver 20 MW of radio frequency power to the plasma for up to one hour. The power will be injected at radio frequencies through what we call "antennas," however, ITER antennas have very little in common with the one attached to the standard radio in our kitchen. These components will measure 1.8 x 3.5 x 2.5 metres and weigh 45 tons (dry weight). And—who would have guessed—there is some very sophisticated technology hidden inside the beast.

It is Europe's responsibility to deliver two of these high-tech components to ITER. In 2010, the ITER Organization signed a Task Agreement with the European Domestic Agency which, in turn, signed a contract for the "build-to-print" design of these impressive antennas with the CYCLE consortium, made up of several European fusion associations with ICRH expertise: CCFE, UK; CEA, France; ERM, Belgium; IPP, Germany; and ENEA-Torino, Italy.

More than 50 experts on ion cyclotron radio frequency design, engineering, and physics met in Cadarache last week for the antennas' preliminary design review, conducted by Jean Jacquinot.

On 22-24 May, more than 50 people—including experts on ion cyclotron radio frequency design, engineering, and physics; representatives from the European, Indian, and US Domestic Agencies; technical representatives from interfacing ITER systems; and, of course, members of the CYCLE design team—met in Cadarache to review the preliminary design. The review panel was chaired by Jean Jacquinot, former director of JET and one of the pioneers of the ICRH technology.

The design of ITER's ICRH antennas will be the quintessence of technologies developed for machines like Alcator C-mod, JET, Asdex-Upgrade, TEXTOR and Tore Supra. "The challenge in designing such an apparatus for ITER is not only the power increase to 10 MW for each antenna and the associated large electric fields," explains Jacquinot, "but the fact that this is a plasma-facing component that has to withstand neutron bombardment and high heat fluxes from the plasma. In addition, these components will require permanent water cooling and they will have to squeeze into an equatorial port plug, allowing only very tight tolerances."

"We try to make use of available technology as much as we can," ITER's Ion Cyclotron Section Leader Bertrand Beaumont comments. "But of course some new developments are necessary, such as the Faraday screen—a sandwich-like structure made of beryllium, hardened copper alloy, and stainless steel that covers the front face of the antenna."

"One of the open questions that call for further study is the behaviour of the ceramic vacuum windows in a nuclear environment," adds Philippe Lamalle, technical responsible officer for the antennas.

"The design review was an excellent and in-depth review of the antenna system, showing us that we are on the right track," said Dharmendra Rathi, technical officer for the system, at the end of the meeting. With no showstoppers identified, the ICRH team will now prepare for the next mileston: the final design review scheduled for 2015.

"The design review was an excellent and in-depth review of the antenna system, showing us that we are on the right track," said Dharmendra Rathi, technical officer for the system, at the end of the meeting. With no showstoppers identified, the ICRH team will now prepare for the next mileston: the final design review scheduled for 2015.