Conductors for 6 out of 18 toroidal field coils manufactured

27 Jul 2012

-

Sabina Griffith

From the 330 tonnes of Nb3Sn strands that have been manufactured, conductors for six toroidal field coils have been produced.

The production of superconducting cables for ITER's large and powerful toroidal field coils is making remarkable progress: as of today, 330 tonnes of strands made out of Nb3Sn, a special alloy made of niobium and tin, have been produced in factories in China, Europe, Japan, Korea, Russia and the United States. In the pre-ITER world, global production was 15 tonnes a year. "The current production status represents 75 percent of the total toroidal field strands required for ITER," reports Arnaud Devred, Section Leader for Superconducting Systems. "Out of these strands, conductors for 6 out of the machine's 18 toroidal field coils have been produced."

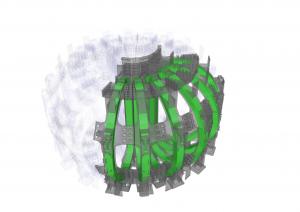

The 18 toroidal field coils will produce a magnetic field around the ITER torus helping to confine and control the plasma inside. The coils are designed to achieve operation at magnetic fields up to 13 Tesla. They are made of cable-in-conduit superconductors in which a bundle of superconducting strands is cabled together and contained in a structural jacket. Unit lengths of theses cables—measuring 760 metres or 415 metres depending on their position within the coil—are then spooled into a D-shaped double spiral called a "double pancake," giving the structure the characteristic shape of ITER's toroidal field coils.

As of today, a total of thirty 760-metre unit lengths and thirteen 415-metre unit lengths have been manufactured by the procuring agencies in Japan, Korea, Russia and Europe, adding up to the material required for 6 of the 18 toroidal field coils.

"Quality tests are currently underway," says Devred, "to confirm that these unit lengths can be accepted for coil winding."