UV light from plasma to etch next-generation chips

3 Sep 2012

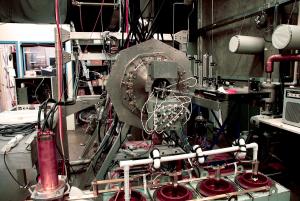

Xenon plasma produced in this laboratory equipment generates the Extreme Ultraviolet (EUV) wavelentgh that should provide the light output that the microprocessor industry needs. © University of Washington

Light is the etching tool industry uses to create the microscopic circuits on the surface of silicon microprocessors. As "chips" follow Moore's law and become more powerful with each new generation, the features on the silicon become denser, meaning smaller structures need to be etched.

The short-wave (193 nanometres) ultraviolet light that is currently used by the industry is neither "sharp" nor powerful enough to meet the next generations' standards. What industry needs is light with an even shorter wavelength—less than one-tenth the present one—that will enable the etching of even finer grooves.

Such extreme ultraviolet light can be created only from plasmas. Scientists at the University of Washington College of Engineering have developed a "low-cost version of a fusion reactor," dubbed ZaP, that should provide the light output that the microprocessor industry needs.

Read the full story here.