Tore Supra ready to go WEST

29 Oct 2012

-

Robert Arnoux

The tungsten plasma-facing componenents to be tested in WEST are fully representative of the high heat flux flat part of the ITER divertor plasma-facing units.

On the other side of the CEA fence, in Cadarache, sits a large tokamak which played an important role in the definition of ITER. Tore Supra, a CEA-Euratom device which began operating in 1988, was the first tokamak to successfully implement superconducting magnets and actively-cooled plasma-facing components.

Over the past twenty-four years, Tore Supra has explored the physics of long-duration plasma pulses, reaching a record of 6.5 minutes in December 2003.

In 2000-2002, Tore Supra was equipped with a new carbon-carbon fibre (CFC) "limiter"—the equivalent of the divertor in ITER—capable of withstanding an ITER-relevant heat load of 10 MW per square metre.

This project, named CIEL for Composants Internes Et Limiteurs, demonstrated that, while CFC performs very well in terms of power handling and compatibility with the plasma, its use results in substantial erosion caused by the physico-chemical reactions between the carbon of the limiter and the hydrogen (deuterium) in the plasma. Further experiments in JET have confirmed these observations.

Now, there are not many options when it comes to choosing the material of a divertor. Fifty years of experience in tokamak technology have narrowed the choice to two: it's either CFC or tungsten. Their respective advantages or disadvantages depend on the plasma regimes they are exposed to (more here).

In ITER, it was originally planned to begin operations with a CFC divertor and replace it with a tungsten one before the start of nuclear operation (deuterium + tritium) in 2027. After years of discussions, panels and reviews, a new plan was established and ITER is now considering doing without the first-phase CFC divertor.

Indeed, substantial cost reductions would be achieved by installing a tungsten divertor right from the start and operating it well into the nuclear phase. This solution would also provide for an early training, during the non-nuclear phase of ITER operation, on how to operate with a tungsten divertor.

The ITER Members, however, have not yet reached a unanimous position on this issue.

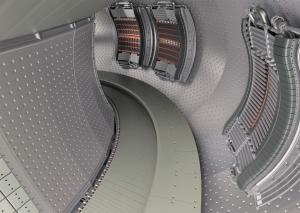

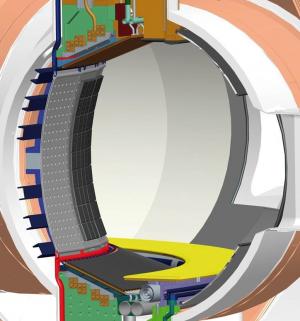

Adapting Tore Supra to accommodate a full tungsten divertor—500 components with a total of 15,000 tungsten tiles—is a challenge CEA-IRFM is ready to take on.

Whatever ITER decides eventually, the tungsten option must be explored. This is what Tore Supra's WEST project (W Environment in Steady-state Tokamak, where "W" is the chemical symbol of tungsten) is about.

"ITER success is CEA's top priority," says Alain Bécoulet, the Head of CEA-IRFM (Institut de Recherche sur la Fusion Magnétique) which operates Tore Supra. "By installing an ITER-like full tungsten divertor in Tore Supra, we can turn our platform into a test-bench on ITER critical path. We can thus contribute to reducing the risk and to saving time and money for ITER. WEST is not something we would add to Tore Supra like we did with CIEL. It's more like Tore Supra becomes WEST to serve ITER."

The CIEL project provided IRFM with a strong experience in cooperating with the industry. Adapting Tore Supra to accommodate a full tungsten divertor—500 components with a total of 15,000 tungsten tiles—is a challenge the Institute is ready to take on. (All carbon will have to be taken out of the device; in-vacuum vessel magnetic coils will need to be installed in order to modify the plasma shape from circular to "D-shaped," and heating systems will have to be adapted to the new configuration.)

The formal decision to go WEST is due to be taken by CEA at the end of 2012. Bécoulet is optimistic: partners are showing interest and "customers" other than ITER appear eager to utilize the future test bench as well. "All fusion machines, present and projected," he says "are expected to go tungsten."

Bringing a timely answer to ITER interrogations means that Tore Supra, which Bécoulet calls "a technological jewel," should prepare to go WEST early in 2013 and be ready for the first experiments in 2015.

Click here to view an animation of the WEST project.