ITER's divertor remote handling system signed off

7 Nov 2012

-

Jim Palmer, ITER Remote Handling Section

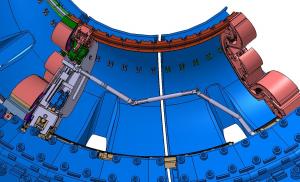

Divertor cassette placement inside the vacuum vessel by means of the cassette toroidal mover (cable handling device deployed).

On Wednesday 31 October ITER Director-General Osamu Motojima and Jean-Marc Filhol, acting head of the European Domestic Agency's ITER Department, signed the Procurement Agreement for the Divertor Remote Handling System (DRHS).

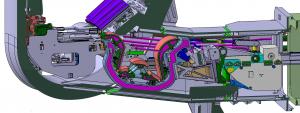

The DRHS provides the means for remote replacement of the ITER divertor system. The divertor handling concept relies on the use of heavy remote handling transporters known as "cassette movers" and dexterous, man-in-the-loop tele-manipulators. The former are required to achieve high-accuracy transport of the 8-12 tonne in-vessel components from their entry point to their operational position in the vacuum vessel. The latter are required to precisely deploy a variety of mobile tools for pipe maintenance, (un)locking of the cassettes from the toroidal rails, (dis)connection of diagnostic cabling, etc.

The DRHS makes use of the remote handling transfer casks to allow safe transport of contaminated/radioactive in-vessel components to and from the Hot Cell Facility.

Due to severe space constraints within the vacuum vessel remote handling port and the lower part of the plasma chamber, it is necessary that cassettes be handled in a cantilevered way. This generates extremely challenging design requirements on the divertor remote handling equipment, both in terms of high mechanical loads and payload position accuracy. The gaps between cassette and vacuum vessel structure may be as small as 12 mm top and bottom at certain points during the transport trajectory.

After operations, the DRHS will be decontaminated, maintained and stored in the ITER Hot Cell. Re-qualification/commissioning of the system will take place on full-scale mockups within the Remote Handling Test Facility (RHTF), also to be located in the Hot Cell building.

Divertor cassette insertion through vacuum vessel divertor port using the cassette radial mover (right side). Divertor cassette toroidal mover in attendance inside the vacuum vessel (left side).

The ITER team and a number of European institutions have been working on the development of the ITER divertor maintenance concept for more than 15 years. The most challenging steps within the process have been demonstrated at full scale, first within the DTP (Divertor Test Platform) constructed in Brasimone, Italy (ITER 1998 design), and more recently within the DTP2 located in Tampere, Finland (ITER 2001 design). This long concept preparation period is now over and with the signing of the Procurement Arrangement and the engagement of an industrial supplier in the next few months, the task of establishing a fully comprehensive, industrialized set of equipment for the remote exchange of the ITER divertor begins.