Measuring current with light

7 Nov 2012

-

Vincent Massault, Head of the Fusion Research Unit, SCK•CEN

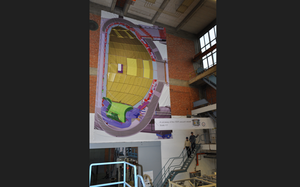

An ITER cross section drawing of scale 1:1 (12 m high by 7 m wide) used as test bed for the Fiber Optics Current Sensor fibre blowing system.

At the Belgian Nuclear Research Center SCK•CEN in Mol, engineers and scientists are developing a system that should enable ITER to measure plasma current in a new fashion. In contrast to the present-day inductive system, the measuring principle developed by the Belgian researchers is ideal for very long shots or even steady state current measurements without the need of signal integration with time.

The measurement is based on a fully optical principle: polarized light is launched in an optical fibre. Following Faraday's law, the light polarization plane is rotated if a magnetic field is applied along the light path. By surrounding the vacuum chamber with a fibre loop, the current of the plasma is completely enclosed. It follows from the Ampere law that the total rotation angle is directly proportional to the enclosed current.

Up until now such systems were only applied for much lower currents and in environments less harsh than that of the ITER Tokamak where radiation, temperature, vacuum, vibrations etc., make existing designs unusable.

The SCK•CEN, with a long experience in radiation-resistant fibre optics, with the support of the ITER European Domestic Agency F4E, is pursuing a sensor design based on fibres with limited sensitivity to radiation. As, due to the environment, it can't be ruled out that the optical fibre may be compromised (i.e., a darkening of the fibre due to irradiation), the sensing fibre could be replaced by a simple intervention from outside of the cryostat: the fibre, installed in a stainless steel tube, could be replaced using a pressurized-air fibre blowing technique. If so, ITER would have the benefit of a measurement system that is easily replaceable.

In practice, however, designing a suitable fibre blowing system in compliance with ITER geometry is a serious engineering challenge. To test the design on a real scale the SCK•CEN installed a 12-metre-high x 7-metre-wide cross-sectional drawing of ITER and positioned the stainless steel tube that will guide the fibre optics along its path around the vessel. The first tests showed that the principle is realistic and will allow for easy replacement of the fibre. The Fiber Optics Current Sensor (FOCS) principle demonstration also comprises ongoing tests at Tore Supra and Textor.

If successful, these efforts will result in the installation of three such measuring fibres around the ITER vacuum vessel. The engineering challenges are being addressed in a collaboration between SCK•CEN and the IRFM (Institut de Recherche sur la Fusion Magnétique) in Cadarache.

If successful, these efforts will result in the installation of three such measuring fibres around the ITER vacuum vessel. The engineering challenges are being addressed in a collaboration between SCK•CEN and the IRFM (Institut de Recherche sur la Fusion Magnétique) in Cadarache.

While plasma current measurements are a traditional diagnostic technique, the SCK•CEN researchers are investigating whether further information can be gleaned from the light signal travelling along the fibre. Detailed analysis of the return signal may result in information on the distributed magnetic field and temperature variations. Possibilities that are still under development ...