A blast of heat for ITER's plasma-facing components

21 Dec 2012

In the vacuum chamber of ITER Divertor Test Facility in Russia, an 800 kW electron gun focuses its heat directly on the target, exposing the materials to the same heat load expected during normal operational conditions in the ITER machine.

The largest facility in the world capable of testing the ITER divertor's plasma-facing components began operation in October at the Efremov Institute in St. Petersburg. A series of high-heat flux tests were performed on the first full-scale prototype of the divertor outer vertical target, which had been manufactured and delivered by the Japanese Domestic Agency.

ITER's divertor components will be manufactured by the European, Japanese and Russian Domestic Agencies. These heat-capturing elements will be in direct contact with the plasma—a first barrier that will withstand the main heat flux from plasma during operation. With plasma temperatures of up to 150 million °C and an expected heat load on the divertor surface up to 20 MW/m2, the components under test have challenging requirements to meet.

"The inner and outer divertor targets are the most highly loaded components of the ITER machine," says the leader of the Tungsten Divertor Section Frederic Escourbiac. "The aim of this testing is to verify the thermal performance of the plasma-facing components, and to make choices about materials and technology before the manufacturing phase."

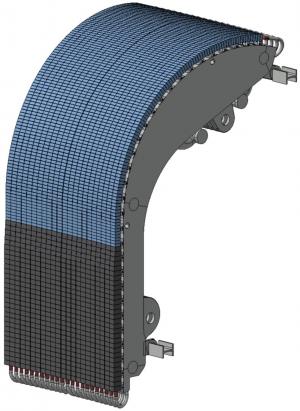

The rounded area of the divertor outer vertical target will receive some of the highest thermal loads of the ITER device.

The ITER Divertor Test Facility in Russia was established following the signature in February 2010 of the Procurement Arrangement for the High Heat Flux Testing of ITER's Plasma-Facing Components. In the vacuum chamber of this unique test facility, an 800 kW electron gun focuses its heat directly on the target, exposing the materials to the same heat load expected during normal operational conditions in the ITER machine.

"This first test series was remarkable in a number of ways," says Frederic. "It was the maiden run for the ITER Divertor Test Facility, allowing our colleagues at the Efremov Institute to verify that all was functioning as planned and to work out the initial kinks. For the divertor program, it was the first opportunity to demonstrate that our scale one components can withstand the demanding thermal conditions of the ITER machine."

The results of the three-week test run are currently under the scrutiny of Frederic, ITER Technical Engineer Andrey Fedosov, and colleagues at the Russian and Japanese Domestic Agencies, and will be reported early in the new year.

Click here to view a video on the high heat flux testing of plasma-facing components (produced by ITER Russia).