Tiny diamond detectors for the giant ITER machine

17 Jun 2013

-

Alexander Petrov, ITER Russia

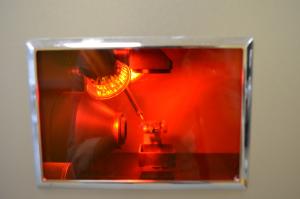

The electronic-grade, single-crystal diamond plates and associated metal fixings are cut to the required sizes and shapes by laser. Pictured: the laser equipment at TRINITI, near Moscow.

In the world of tokamaks ITER will be a giant, weighing some 23,000 tonnes and measuring 30 x 30 metres. Whatever its might, however, the operation of this giant couldn't be successful without such tiny elements as diamond detectors. These small components, only 4 x 4 x 0.5 mm, are an important part of one of ITER's neutron diagnostics, the vertical neutron camera.

The diamond detectors, part of the Russian Domestic Agency's procurement responsibilities for ITER diagnostics, will be manufactured at a dedicated facility at the Troitsk Institute for Innovation and Fusion Research (TRINITI) near Moscow.

Manufacturing is a sophisticated and multi-stage process, according to Nikolay Rodionov who heads the facility: "In ITER, detectors will operate under high neutron flux and high temperature, and it will be our task is to produce diamond detectors that are capable of withstanding such extreme, severe conditions."

At the beginning of detector manufacture, the key elements—electronic-grade, single-crystal diamond plates—arrive at the material analysis laboratory where highly sensitive instruments test quality and identify defects. Next, the plates and associated metal fixings are cut to the required sizes and shapes by laser.

An ion beam of oxygen or argon provides additional cleaning and purification. For the diamond detectors, even the smallest impurities are inadmissible.

To correct possible defects, the single crystal diamond plates are annealed in a high-temperature vacuum oven at temperatures no less than 1500 degrees Celsius. Rid of their organic impurities by specially mixed acids, the diamond crystals are exposed to additional purification from an ion beam of oxygen or argon.

For such a sensitive component as a neutron detector, even the smallest impurities are inadmissible.

In the next stage of manufacturing a metal layer (gold, titanium, platinum or aluminum) is deposited on the diamond plate and gold or aluminum current conductors are welded on—these conductors, which at 30 micrometres thick can hardly be seen by the naked eye—collect electric charge from metal contacts. Now the detector, placed into a special mounting of thin sapphire plate and attached by two membranes of bronze or copper, is ready for installation on the vertical neutron camera.

By 2018, the specialists at TRINITI will have manufactured approximately 100 diamond detectors for ITER, including test samples, prototypes and spares. Currently, the facility has been equipped with laboratory and technical equipment for the manufacturing of dummies and test samples. For the production of prototypes and the beginning of batch manufacturing of qualified diamond detectors, additional modernization is planned to meet the requirements of the complex manufacturing operations for the diamond detector.

Click here to view a video on the manufacturing of ITER diamond detectors.