Cryopump redesign saves time and money

20 Nov 2013

The redesign of the neutral beam and MITICA facility cryo-sorption pump will result in faster manufacturing at a significantly reduced cost. The review panel was united in its positive endorsement of the design.

Last week a team of international experts put the ITER final design of the neutral beam and MITICA facility cryo-sorption pump under scrutiny in a thorough review. This comes before the ITER Organization releases the "build to print" design for the first pump to be manufactured for the Neutral Beam Test Facility Facility (NBTF) in Padua, Italy.

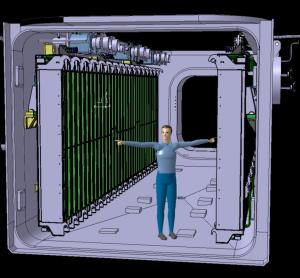

"The pump is an essential part of the ITER neutral beam system and can pump with speeds of up to 4.7 million litres per second," reports Matthias Dremel, vacuum pumping engineer at ITER. "This cryopump, which will be the world's largest cryo-sorption pump, has been challenging in engineering terms to design."

Vacuum Section Leader Robert Pearce agrees. "In a period of about one year the pump has been completely redesigned at ITER in order to produce a design which can be manufactured in a shorter time and at significantly reduced cost. Overall we have a higher integrity design which will save more than two years in the manufacturing schedule and around EUR 25 million."

A thorough review for the world's largest cryopump. Participants include (sitting, right to left): Robert Pearce, Chair Alan Kaye, Wolfgang Obert, Stamos Papastergiou and Christian Mayaux. Standing from right to left (front row): Matthius Dremel, Ron Reid and Ron Hemsworth.

The independent review panel of six experts was chaired by Alan Kaye, former Chief Engineer of JET. More than 40 engineers participated in the review which included representatives of the European and Indian Domestic Agencies, RFX Padua and industrial specialists. The reviewers commended the excellent work of the Vacuum Section design team, expressing appreciation for the high standards and also for the innovation of the novel design which solved all key issues. The review panel was united in its positive endorsement of the design.

The Vacuum Section now has the green light to start the preparation of the procurement of the first pump which is to be used in the Neutral Beam Test Facility in Padua, Italy.