Signature time in Monaco

11 Dec 2013

-

Sabina Griffith

Left to right: Alexander Alekseev, ITER DDG for Tokamak; Osamu Motojima, ITER Director-General; Henrik Bindslev, Director of Fusion for Energy; Kani Fujiki, Head of Delegation to the 13th ITER Council; and Sriram Kattalai Ramachandran, ITER Director of Finance & Budget.

Taking advantage of the presence of representatives from all ITER Domestic Agencies at the MIIFED 2013 conference held in Monaco last week, the ITER Organization was able to conclude five Procurement Arrangements and one Memorandum of Understanding.

On Monday 2 December, a Procurement Arrangement was signed with the US Domestic Agency for the development of ITER's pellet injection system, which will fuel the plasma by firing frozen deuterium and tritium pellets. The pellet injection system is also capable of controlling the frequency of Edge Localized Modes (ELMs) by injecting smaller pellets of frozen deuterium at the edge of the plasma at high rates.

The Oak Ridge National Laboratory, with a long history of success in the development of pellet injection systems for the JET tokamak (UK), TFTR (US), the DIII-D tokamak (US) and other fusion devices, will collaborate with US ITER. To meet the challenging requirements for the ITER pellet injection system, which far exceed those for any other system in operation, ORNL has launched an R&D program to develop an ITER-scale pellet injection system prototype incorporating all the key technologies necessary for the ITER system. A prototype test program using supercritical helium cooling from the Spallation Neutron Source at ORNL is planned as part of the Procurement Arrangement.

Left to right: Director-General Motojima, Kani Fujiki and Eisuke Tada, head of the Japanese Domestic Agency.

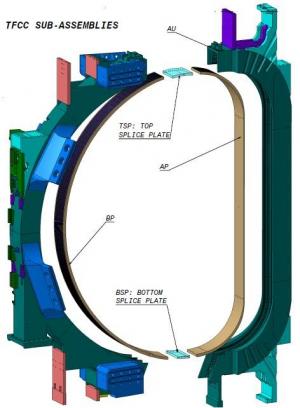

The Toroidal Field Coil Structure Procurement Arrangement was signed on Tuesday 3 December by three parties—the ITER Organization, the Japanese Domestic Agency and the European Domestic Agency. Each of ITER's 19 toroidal field magnets (18 for operation, plus one spare) is enclosed in a thick, "D" shaped steel structure called the toroidal field coil case. Procurement of the 19 coil cases is the responsibility of Japan; however, as part of the agreement to site the ITER Project in Europe, ten of the coil cases will be paid for by Europe.

And finally three Procurement Arrangements dedicated to ITER's electrical power distribution systems were signed on 3 December with the European Domestic Agency: Steady State Electrical Network (SSEN) and Pulsed Power Electrical Network (PPEN) Installation; Emergency Power Supply; and the manufacturing and delivery of SSEN Components.

To allow insertion of the winding pack during manufacturing of the toroidal field coils, the coil cases are split into four main subassemblies.

For both the European Domestic Agency and ITER's Electrical Engineering Division, these three signatures are major milestones because "now everything is ready for the fabrication and installation of ITER's two electrical networks," stressed Division Head Ivone Benfatto following the signatures. "In particular, the SSEN must be ready by 2016 to supply the power for the commissioning of ITER's major plant systems."

A Memorandum of Understanding was also concluded during MIIFED 2013 for the common manufacture of ITER's 44 port plugs. Japan was the second Domestic Agency to sign the Memorandum following the signature of India in July. The objective is to have the ITER Domestic Agencies involved in port plug procurement contract with one single manufacturer, in order to benefit from the advantage of having one standard for design, quality assurance, and qualification and manufacturing methods.

A Memorandum of Understanding was also concluded during MIIFED 2013 for the common manufacture of ITER's 44 port plugs. Japan was the second Domestic Agency to sign the Memorandum following the signature of India in July. The objective is to have the ITER Domestic Agencies involved in port plug procurement contract with one single manufacturer, in order to benefit from the advantage of having one standard for design, quality assurance, and qualification and manufacturing methods.