A five-storey "Diagnostic Hotel"

19 Mar 2014

-

Krista Dulon

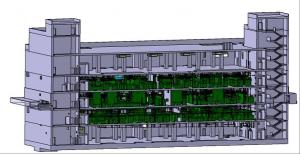

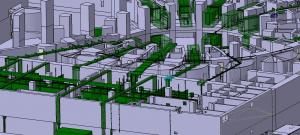

Each diagnostic system will be assigned a room on one of the three central floors of the Diagnostics Building. Top and bottom floors will house the ventilation systems, cooling units and cable trays.

Diagnostic instruments will be distributed throughout the ITER vacuum vessel, as near as possible to the plasma in order to capture information for plasma control, machine protection, and an understanding of plasma physics.

But the back ends—the electronic and information systems that will receive, record and interpret signals from the operational arena—must be situated at a distance, well protected from the nuclear and thermal loads of the Tokamak.

In February work was completed on the concrete basemat for the Diagnostics Building, a 40 x 80 metre, five-storey structure that will house most of the back-end systems for ITER diagnostics. Situated outside of the bioshield that will surround the ITER Tokamak, but part of the same suite of buildings to be built on nuclear foundations in the Seismic Pit, the Diagnostics Building will remain accessible to technicians.

"On an average day, no frequent human intervention will be necessary within the Diagnostics Building," explains Victor Udintsev, who leads the Common Port Plug and Engineering Sub-Section. "Data coming from the diagnostics will be monitored from the Control Room, where approximately 20 percent of operators will be assigned to diagnostics. But technicians can enter the building and spend time in the event that repairs or testing are necessary."

The concrete basemat for the Diagnostics Building, located to the south of the machine, was completed in February.

Walking through the hallways of the Diagnostic Building would feel a little like walking along the corridors of a hotel—flanked on every side by closed doors with room numbers and the names of the systems enclosed within. "One room has typically been reserved for every system," says Victor. "Behind the doors, you'd find the complete back-end systems, including electrical cubicles, electronics, computers and control units."

And, despite its name, in addition to back-end diagnostics the Diagnostics Building will also house CODAC and other systems.

And, despite its name, in addition to back-end diagnostics the Diagnostics Building will also house CODAC and other systems.

Diagnostic signals will be transported out of the Tokamak an average of 25 metres, and in some cases as much as 40 metres, along waveguides, cables or fibre optics. Each central floor of the Diagnostics Building is built to match a level of the vacuum vessel (lower, equatorial or upper).

Construction will start this year on the Diagnostics Building and is slated to last approximately two years. In late February, a meeting was held to review the space allocations, interfaces, geometrical conflicts and possible mitigation measures for Level L2 of the building; this work will be pursued level-by-level before construction can begin.

Diagnostics signals will leave the operational arena along waveguides, cables or fibre optics and travel as much as 40 metres to the back-end electronic and information systems.

Diagnostic Engineer Thibaud Giacomin is charged with the integration of many of the back-end systems into the Diagnostics Building. "We will have diagnostic systems coming from all seven ITER Domestic Agencies; in addition to the systems, they will deliver the electronics, the control systems and the software. We need to define the location of each diagnostic; we need to think about all the services needed for the equipment (gas, power, water); and we need to evaluate the weight of each part and provide this data for the building in order to make all the necessary calculations, for example seismic calculations."

"One of the greatest challenges for our team is the alignment of diagnostic schedules with those of building construction and machine assembly," says Victor. "We must have all Domestic Agencies on board for maximum coordination. We are confident that we will succeed."