Ion source power supplies successfully tested in Italy

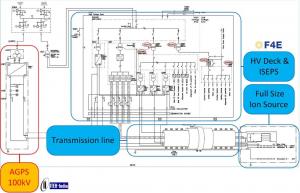

On 14 May 2014, the last components of the ion source and extraction grid power supply (ISEPS) successfully passed factory acceptance tests at the supplier facility in San Giorgio di Piano, Italy (OCEM Energy Technology). The radio frequency power supplies and the DC power supply (provided by OCEM) and the radio frequency generator (provided by sub-contractor Himmelwerk from Germany) were tested on dummy load.