Managing complexity with good processes

13 May 2015

-

Alex Martin (Design Integration) and Angela Saenz (Project Control Office)

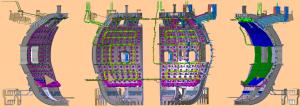

The ITER in-vessel configuration, representing (from left to right) the in-vessel diagnostics, the in-vessel coils, the blanket manifolds and the blankets.

The inner workings of the ITER Tokamak are highly complex, not only because of the sheer number of components but also due to the elaborate interconnectivity between them. Over 600 components among the blanket, the divertor and the port plugs act as plasma-facing elements, covering a surface area of 875 m2. Hundreds of other components are placed between these elements and the vacuum vessel.

The technical complexity, the variations in schedule, and the number of supplier interfaces at each Domestic Agency add an extra dose of challenge.

A team of seven, led by Tokamak Integration Responsible Officer Alex Martin, has worked intensively to come up with a design approach that allows the components and their interfaces to mature at the same pace.

This integrated approach involves considering all the components inside the machine as a single system. A cross-functional team has been put in place involving a high degree of collaboration between the design teams of the vacuum vessel, in-vessel diagnostics, in-vessel coils, blanket manifolds, blankets, first-wall diagnostics, the divertor, divertor diagnostics and port plugs. In this approach, the designs of all the components are updated periodically. An assessment of how well this configuration works is then performed, informed by feedback from both the teams working in component development and manufacturing and those in system management (i.e., tolerance analysis, nuclear analysis). The necessary design trade-offs are then performed and the designs adjusted.

This iterative process will conclude with the successful delivery and installation of the components forming the in-vessel system.

For their teamwork, collaboration and effort in the construction of a coherent in-vessel configuration integration design, the team composed by Alex Martin, Anne Arnould, Jorge González, Patrick Martin, Gonzalo Martinez, Charles Millot and Flavien Sabourin received a commendation during the ITER Recognition Ceremony held in December 2014.