The tritium breeding challenge

6 Jun 2015

-

Luciano Giancarli, Section Leader, Tritium Breeding Blanket Systems

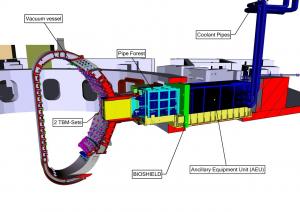

In a fusion power plant, tritium will be produced within the tokamak when neutrons escaping the plasma interact with lithium contained in the blanket. ITER will experiment different tritium breeding solutions via Test Blanket Modules (TBM).

On 20-22 May, the committee charged with the governance of the Test Blanket Module (TBM) Program convened at ITER Headquarters for its 13th meeting. The TBM Program Committee meets twice a year to review the various aspects of the ITER TBM Program and to advise the ITER Council on the implementation of this program to test tritium breeding modules in ITER—a key step in demonstrating tritium breeding self-sufficiency.

The three-day meeting kicked off with a presentation by ITER Director-General Bernard Bigot on the action plan that has been underway since his appointment and the ITER Central Team's involvement in the TBM program, including increased cooperation with the ITER Members and Domestic Agencies.

The Program Committee noted with satisfaction that all six TBM Arrangements (TBMAs) have now been signed. This is a major achievement, since the documents represent the commitment of the ITER Central Team and the ITER Members to the implementation of the TBM Program. The set of six Arrangements covers the period up to the on-site delivery of six Test Blanket Systems and common elements—in total, over 600 components.

Conceptual design review meetings have already taken place for three Test Blanket Systems: the Helium-Cooled Ceramic Breeder (China), the Water-Cooled Ceramic Breeder (Japan) and the Helium-Cooled Ceramic Reflector (Korea). A presentation on the main design issues identified during the reviews—and their proposed resolution—was made to the TBM Program Committee. The conceptual design reviews for the three remaining Test Blanket Systems will be performed between June and September 2015, with the full review process completed by the end of the year.

Good progress has also been recorded in the R&D activities carried out by all seven ITER Members for the TBM program and the main milestones in relation to the activities planned for 2015 and 2016 were verified and confirmed.

In an important step towards the implementation of a framework for managing the intellectual property related to Test Blanket System activities, the ITER Central Team submitted a preliminary proposal concerning the management of Member restricted-access documentation and data that will be delivered to the Organization. Discussion ensued and the proposal will be finalized on time for the 14th Program Committee meeting in October.

On 20-22 May, the committee charged with the governance of the Test Blanket Module (TBM) Program convened in the ITER Council Chambers for its 13th meeting.

Work is also underway to develop a strategy to implement European regulations on nuclear pressure vessels (ESP/ESPN) in the TBM designs. Specific design rules are under development for the recently developed low-activation ferritic/martensitic steels used as TBM structural materials.

The 13th Program Committee also noted the impact of several ITER project change requests on the Test Blanket System design activities and the redesign effort required.

The Program Committee took note of a proposed list of contents for a future trilateral agreement on Test Blanket System radwaste that will need to be signed between the Host State, the Members and the ITER Organization before the start of Test Blanket System manufacturing. The Committee also noted progress in the activities of Agence Iter France (AIF). In particular, it was noted that ANDRA (the French agency for the management of radioactive waste) has completed the preliminary report on the acceptance of the Test Blanket System radwaste in its repositories and that no showstoppers have been identified.

Finally, the Program Committee nominated ITER Organization's Jaap van der Laan as the new chairman of the Test Blanket System radwaste management working group.