Magnet instrumentation contract running smoothly

23 Nov 2015

-

ITER Magnet Division, Instrumentation team

The temperature sensor test facility, the CEA project team, and a delegation from the ITER Magnet Division at the contract steering committee meeting held in November 2015.

The ITER magnet system requires cryogenic temperature and helium flow measurements to control and protect the cryogenic cooling of the coils, coil structures, busbars and current leads. The instruments that supply the measurements need to be accurate and reliable, and also capable of operating in the very harsh environment of the cryostat and the ITER magnet feeders.

Although the measurement solutions planned for ITER are based on proven technologies, particular attention is being paid during the qualification phase to measurement performance, compliance with environmental constraints, and installation feasibility.

All of the magnet instrumentation and control components are procured directly by the ITER Organization. As many of them will be installed by the ITER Domestic Agencies involved with coil and/or magnet feeder fabrication, the ITER Organization must—in addition to procuring the instrumentation—manage the delivery of the components in due accordance with supplier manufacturing schedules.

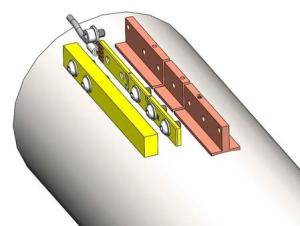

A temperature sensor and its support. Some 2,200 cryogenic temperature measurement chains are included in the scope of the contract between the ITER Organization and the CEA.

The ITER Organization has selected the French Alternative Energies and Atomic Energy Commission, CEA, as the supplier for both the cryogenic thermometers and the Venturi tubes for helium flow measurement. Two contracts have been placed, whose scope encompasses the design, qualification, calibration and fabrication of 2,200 cryogenic temperature measurement chains (a sequence of components) and 280 Venturi tubes.

This success has been made possible thanks to the efficient collaboration between the ITER Organization and the CEA.

Today these two contracts are running smoothly: the design phase for both is fully completed, and temperature sensor supports are routinely delivered to the Domestic Agencies. The manufacture of the Venturi tubes will start next month and series production for the temperature sensors in early 2016.

This success has been made possible thanks to the efficient collaboration between the ITER Organization and the CEA.