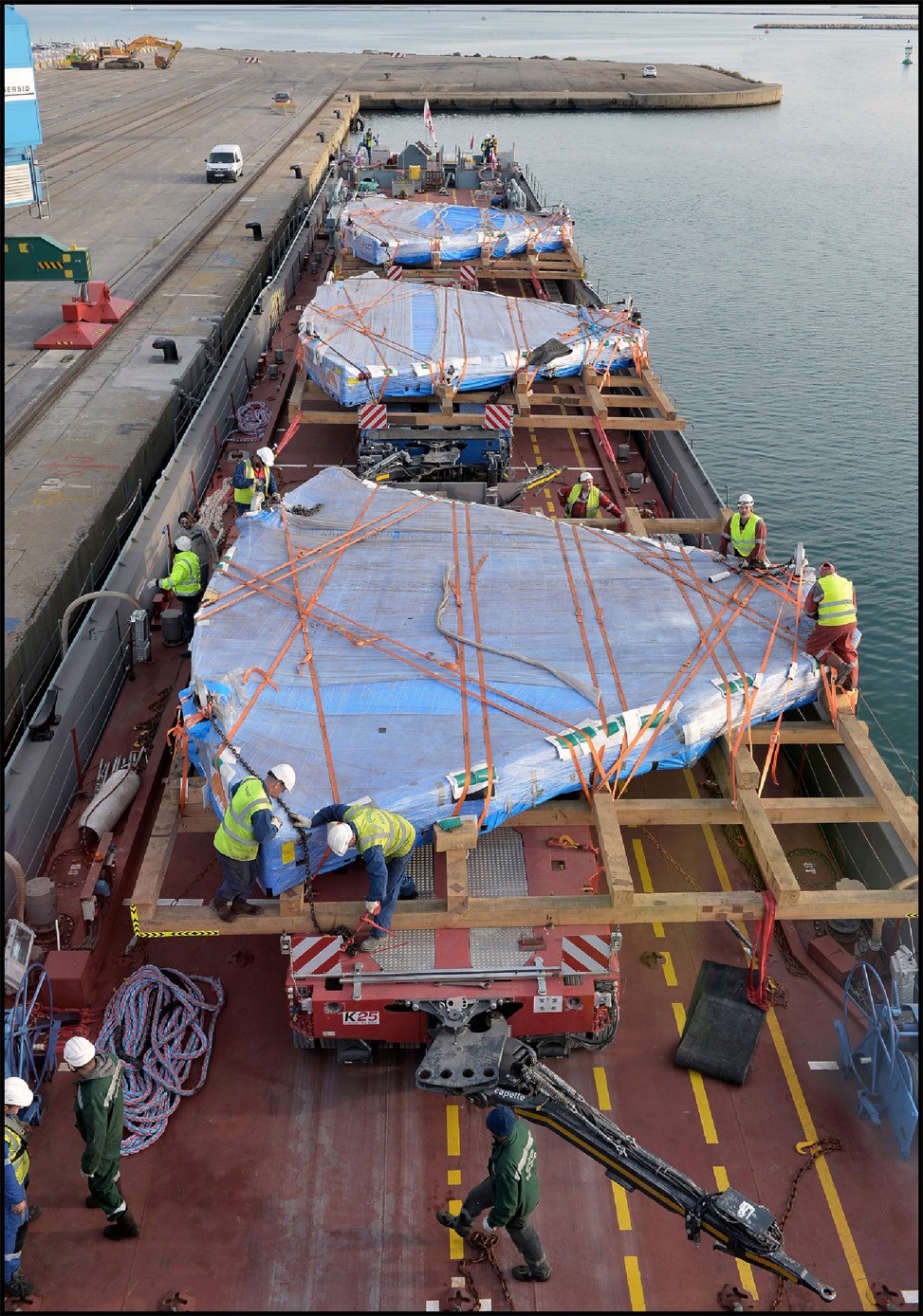

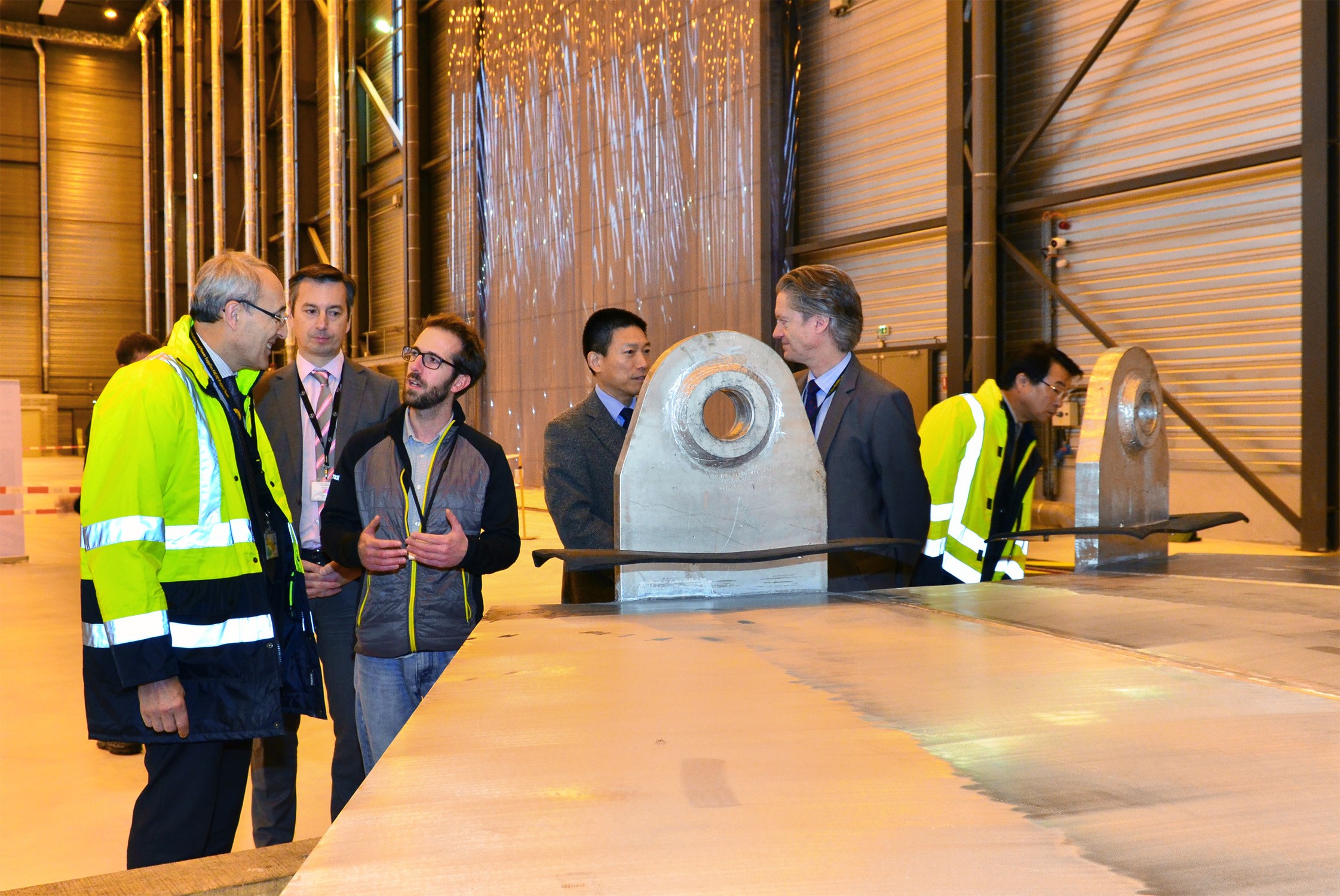

Unloaded, delivered, unwrapped...

The three-trailer convoy that passed the ITER gates at 2:30 a.m. on Thursday 10 December held a strong symbolic significance for all those involved in the project.

For the first time, actual elements of a machine component were being delivered. Shaped like so many slices of pie, the three 60-degree segments belong to one of the most critical components of the machine: the ITER cryostat, the huge steel cylinder that will act as a "thermos" to maintain the ultra-cold temperature of the superconducting magnets and that will provide structural support as well as penetrations to the vacuum vessel and magnet systems.

However large and impressive, the three 50-tonne elements delivered to ITER are but a small part of the completed component, representing only 1/25th of the mass of the cryostat (3,850 tonnes). ITER's cryostat will be the largest, and also the most complex, stainless steel high-vacuum chamber ever built.

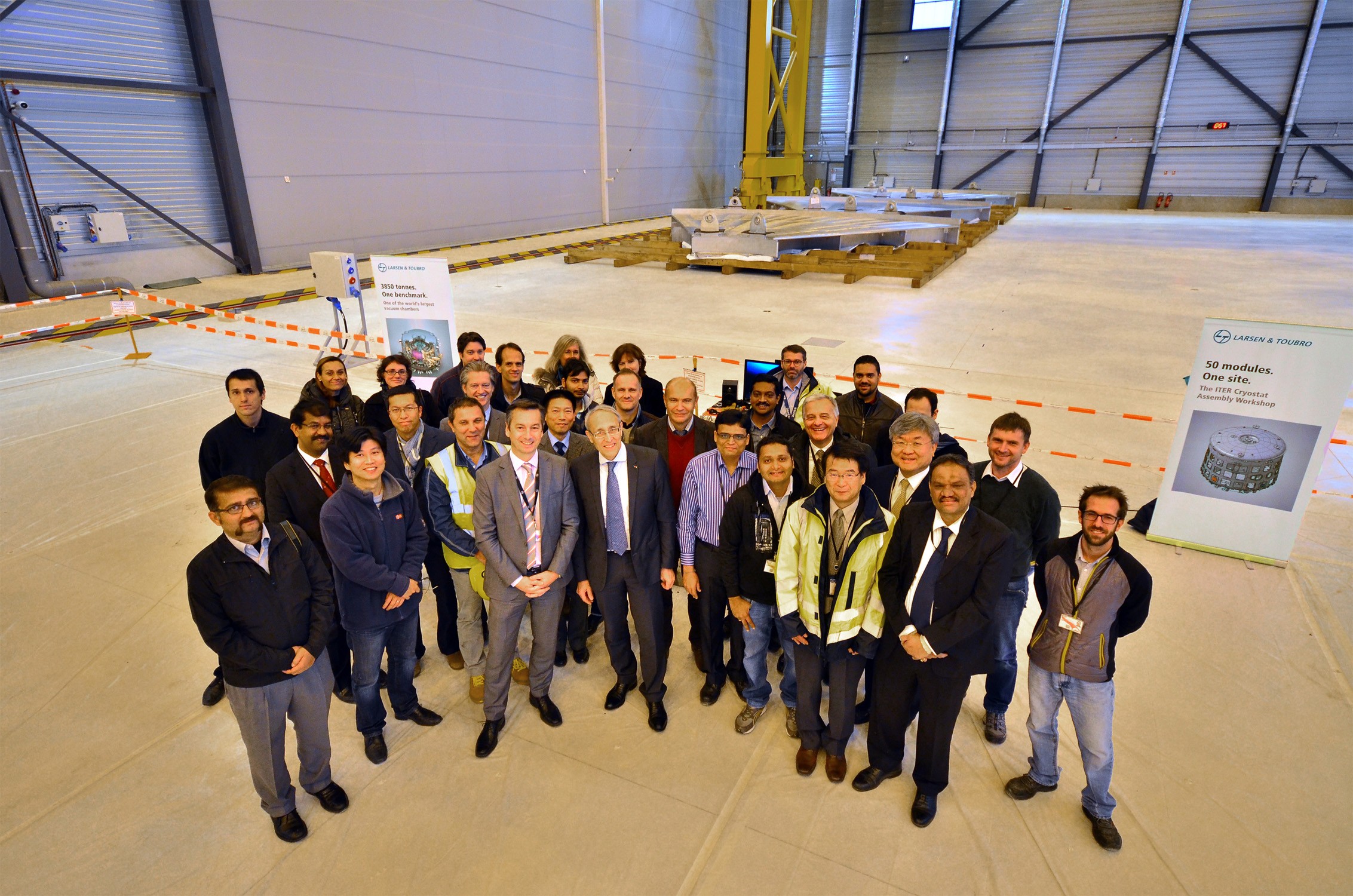

Once all segments and additional parts have been delivered, unpacked and stored in the Cryostat Workshop, ITER will have achieved the first milestone validated by the ITER Council during its November meeting for the years 2016-2017 ─ one that was scheduled for the first quarter of 2016.