Further validation for ring magnet fabrication

20 Feb 2017

-

R.A.

Once a component mockup has been produced—and before fabrication can begin on the actual component or system—a manufacturing readiness review is required to ensure that materials, tools and procedures meet the approbation of the ITER Organization.

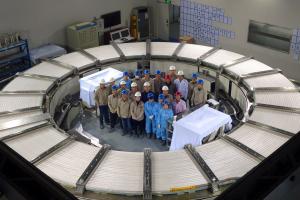

PF6—the second smallest of the ring-shaped magnets that circle the ITER Tokamak (Ø 10 metres)—will be manufactured at the Institute of Plasma Physics of the Chinese Academy of Science, ASIPP, in Hefei for the account of the European Domestic Agency.

Recently, separated by only a few weeks, manufacturing readiness reviews were held on opposite sides of the globe for poloidal field coil dummy double pancakes—in China for poloidal field coil # 6 (PF6) and in southern France at ITER for poloidal field coil #5 (PF5).

PF6—the second smallest of the ring-shaped magnets that circle the ITER Tokamak (Ø 10 metres)—will be manufactured at the Institute of Plasma Physics of the Chinese Academy of Science, ASIPP, in Hefei for the account of the European Domestic Agency; nearly twice as large, PF5 (Ø 17 metres) will be manufactured directly by Europe in the Poloidal Field Coils Winding Facility on the ITER site.

On opposite side of the globe, PF5—with a diameter nearly twice as large as that of PF6—will be manufactured directly by Europe in the Poloidal Field Coils Winding Facility on the ITER site.

Poloidal field coils are made of spiralled coils of conductor called double pancakes, stacked together and hardened into a rigid assembly by way of resin impregnation. PF6 will be made from nine such double pancakes, while PF5 will be formed from a stack of eight. In order to realize full, two-layer dummy mockups, two 718-metre unit lengths were used for PF6 and two 737-metre unit lengths for PF5.

As part of the qualification of the winding tooling and processes, these mockup pancake windings were validated by manufacturing readiness reviews earlier this year, giving the green light for the start of real double pancake winding for both poloidal field coils.

In a similar manner, the next stage—vacuum impregnation—will be reviewed once the impregnation operations have been completed on the mockups and verified, opening the way for this step to be carried out on the production double pancake windings.