A milestone achieved at Taekyung Heavy Industries (THI) in Changwon in early May brings the ITER project one step closer to the start of its tokamak assembly phase.

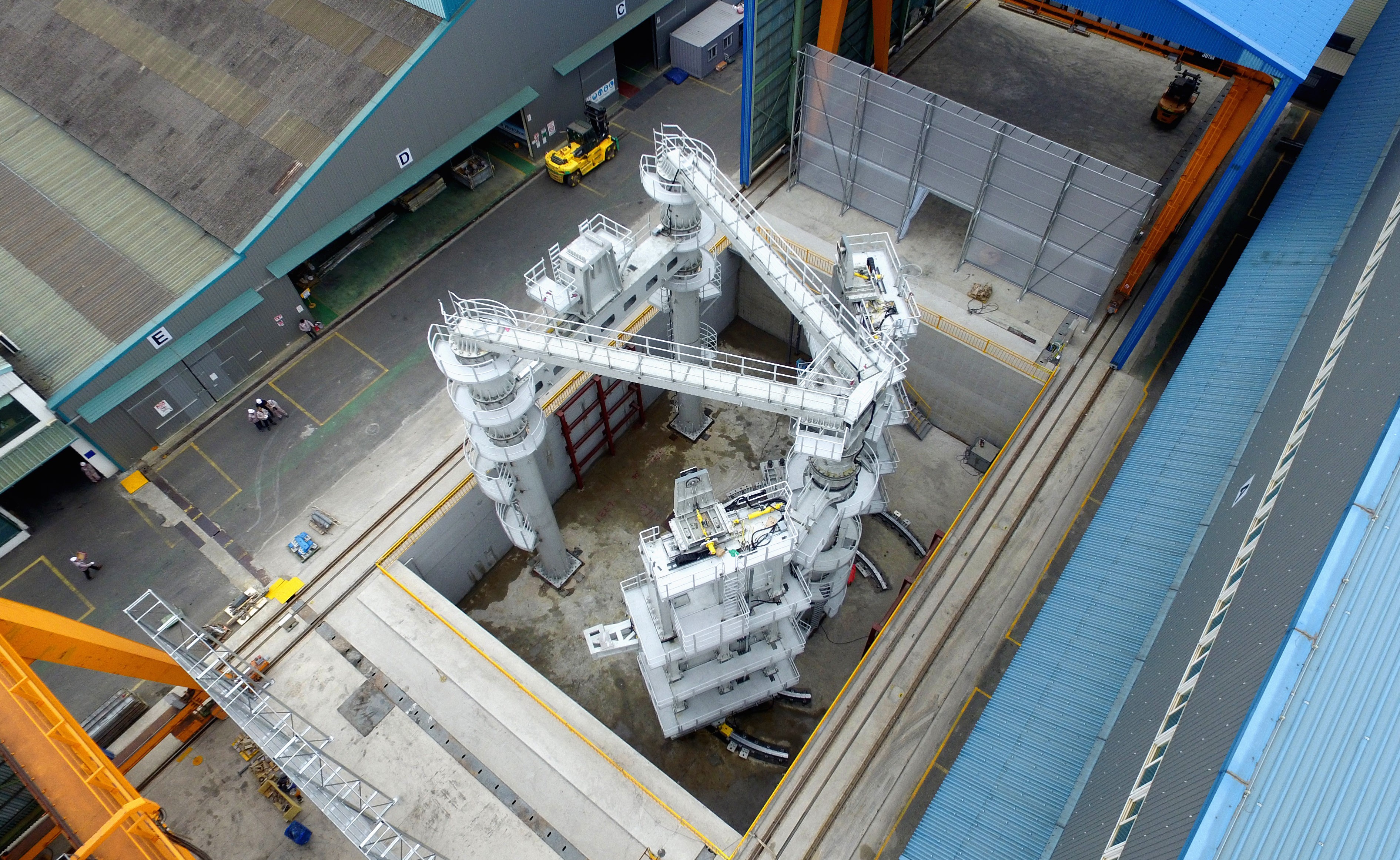

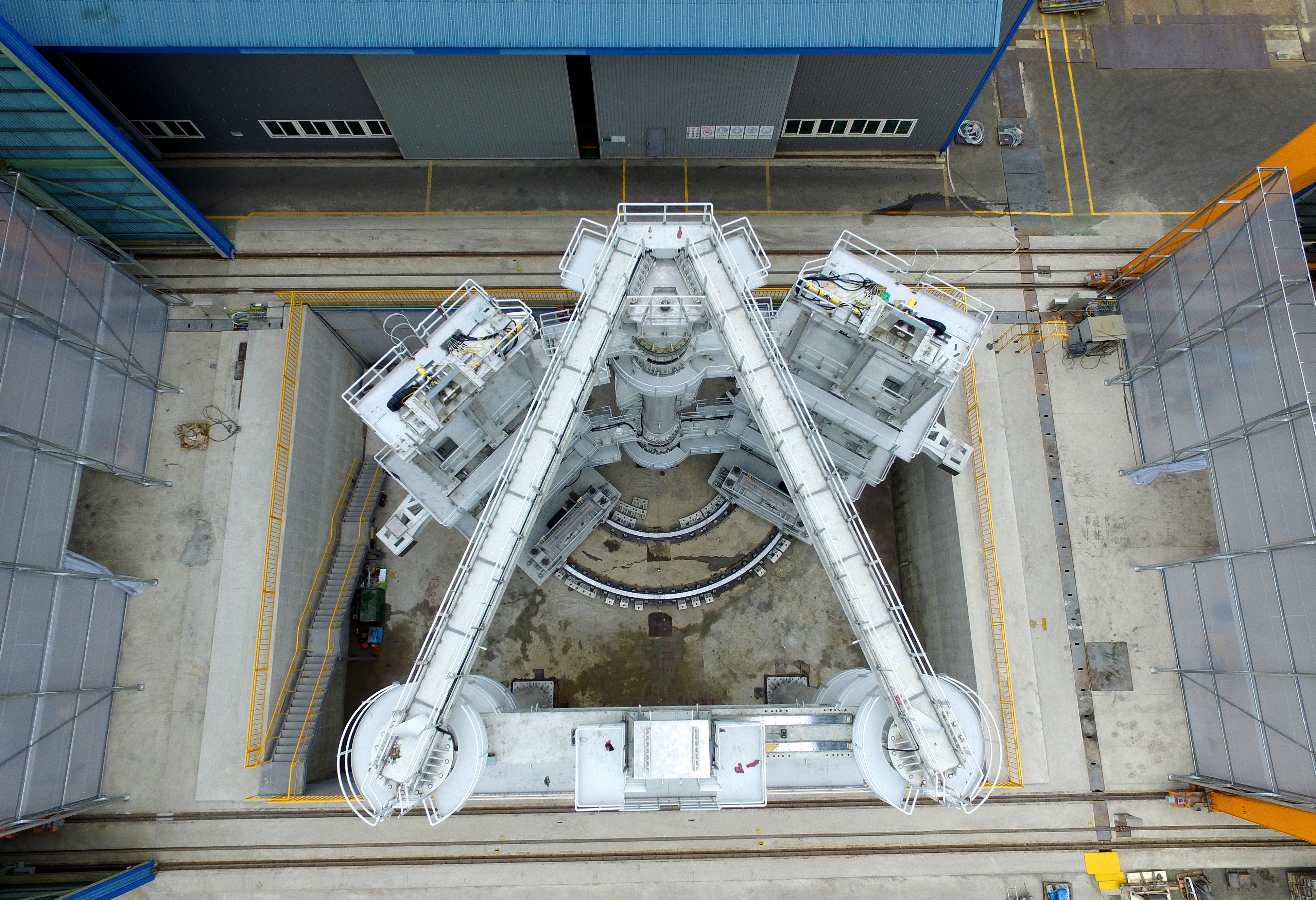

The first vacuum vessel sector sub-assembly tool (SSAT) has demonstrated all functional performance in factory acceptance tests conducted in the presence of observers from the ITER Organization and the Korean Domestic Agency. The tool has now been taken down and packed for shipment to the ITER site—over 800 tonnes of metal plus auxiliary components packed into 90 shipping crates that will ship in five batches.

The first batch, containing lower elements plus all hydraulic activators and accessories, shipped this weekend and is expected to arrive on 30 June.

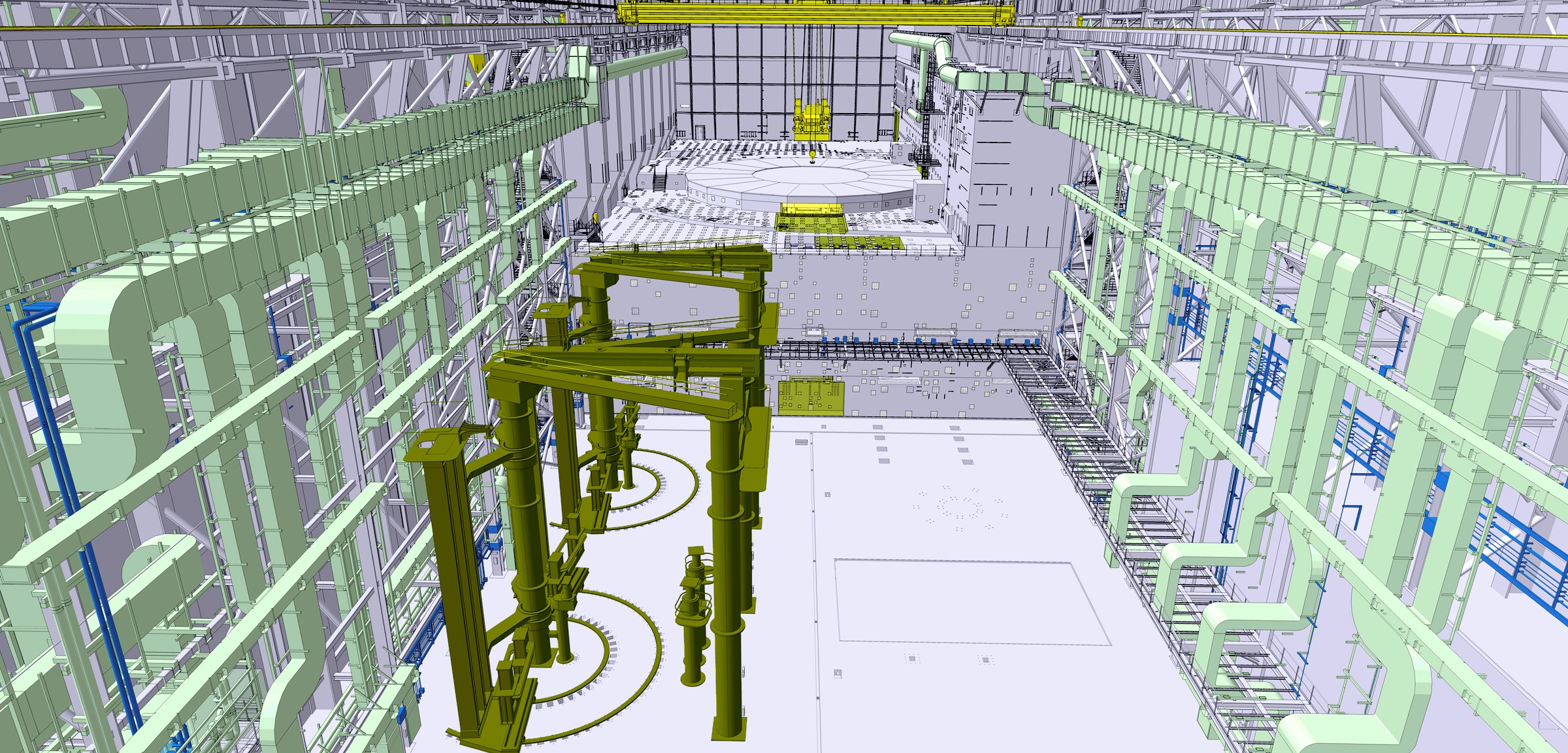

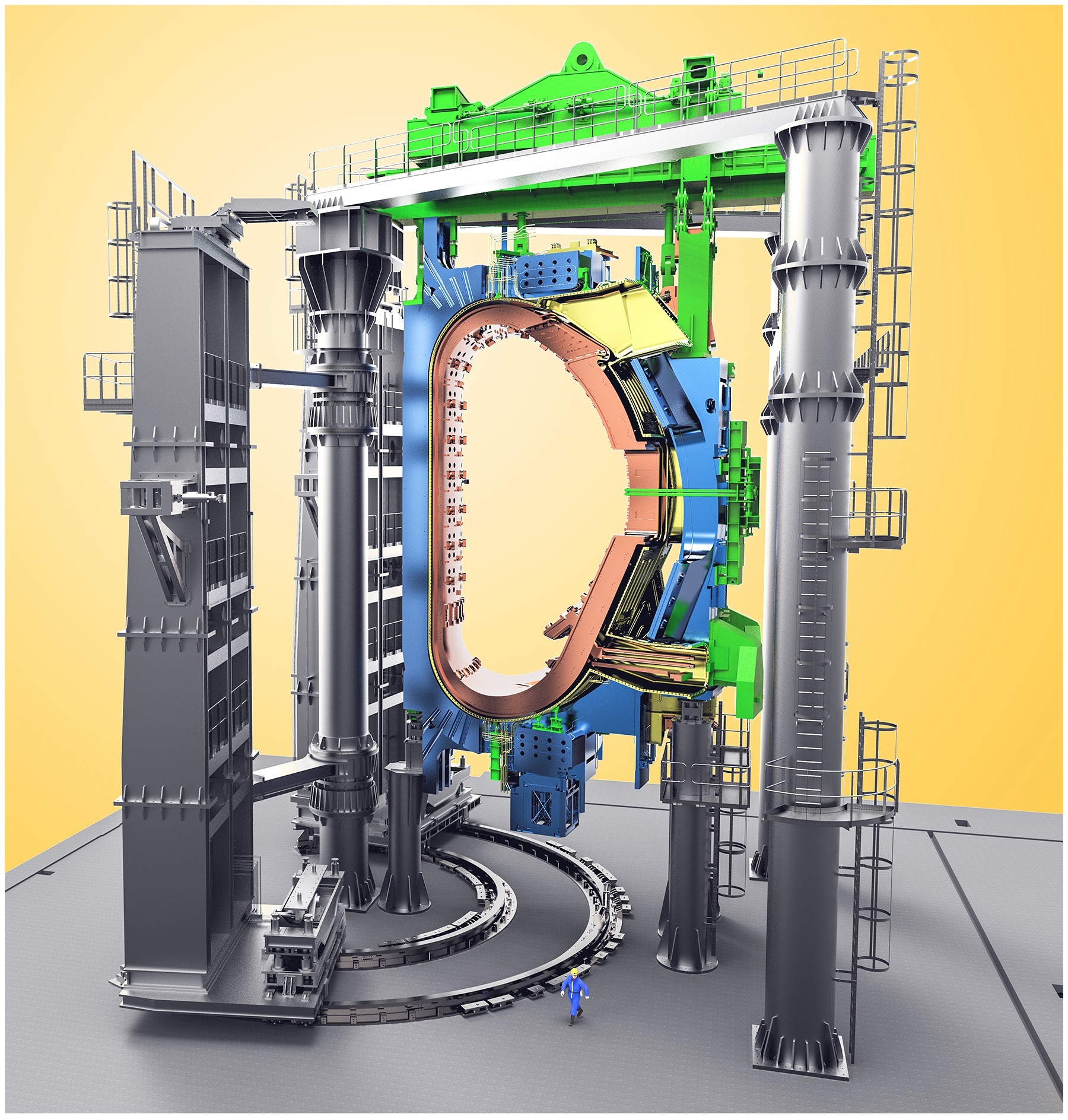

From their location in one area of the ITER Assembly Building, two identical SSAT tools will support the weight of 440-tonne vacuum vessel sectors within the triangle formed by three large columns, as lateral wings slowly rotate thermal shielding and two 310-tonne toroidal field coils into place. The challenge of the operation—reflected in the careful

design and prototyping phase of the tools—is in assembling large and very heavy components to extremely unforgiving tolerances. (More on the tool's hydraulic system and actuators

here.)

The first of the twin tools was manufactured in segments by the Korean contractor THI and then assembled completely at the factory for inspection and testing (see the

video in this issue). Lessons learned on the realization of the first tool will serve in the fabrication of the second, which has started now in Korea.

In a ceremony held on 11 May the head of the Korean Domestic Agency, Kijung Jung, celebrated the completion of the first tool: "This is a step forward for procurement efforts for ITER in Korea and for the project as a whole. Like all ITER Members, Korea's participation in ITER contributes to our industrial and scientific capabilities and positions our nation to be a future player of consequence in the promising domain of fusion."

The months ahead will be a busy time in the Assembly Hall and adjacent Cleaning Facility at ITER. On the reinforced slab that has been prepared for the SSAT tools, contractors have already embedded anchor bolts onto which the rail base plates will be mounted when access to the Assembly Hall becomes possible in mid-August. A few metres away, in the Cleaning Facility, a large storage area is in the planning stages for the components that will arrive starting late June from Korea. In the shape of a 10-metre tall enclosed "box," the storage unit will protect the SSAT components from ambient dust and the other activities underway in the building. When access is possible for the first assembly operations (mid-September), Taekyung Heavy Industries, as the main contractor, and subcontractor CNIM (France) will proceed by first installing the rail components on the basemat and then moving on to assembly of the structural elements of the tool.

Three months will be necessary, meaning that by the end of the year the first SSAT tool will be standing tall in the Assembly Building.