An AC/DC adapter ... ITER size

22 May 2017

-

R.A.

Like flashlight and smartphones, the ITER magnets—all 10,000 tonnes of them—will run on direct current (DC). And like flashlight and smartphones they will need an "adapter" to convert the alternating current (AC) coming out of the electrical distribution network.

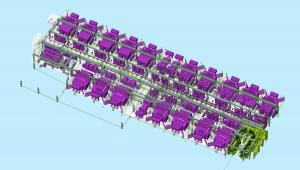

Densely packed with electrical converters, switches and fast discharge units, the twin, 150-metre-long Magnet Power Conversion buildings act as an AC/DC converter for the ITER magnetic system.

The difference, as with most things ITER, is in the size: the outlet is a combination of a four-hectare 400 kV switchyard and a set of three giant transformers; the "adapter" is a set of two 150-metre-long buildings—the twin Magnet Power Conversion Buildings—densely packed with electrical equipment.

The parallel however stops here. There is a system that neither the flashlights nor the smartphones require, yet that is essential for the safeguard of the ITER magnets—the fast discharge units.

The procurement responsibility for the electrical equipment in the buildings is shared by Korea, China and Russia. Pictured here is a converter manufactured in Korea. All and all, the twin buildings will house 32 converter units and some 2.5 kilometres of busbars.

"The ITER magnet system can store up to 50 gigajoules (GJ) of energy," explains Ivone Benfatto, head of ITER's Electrical Engineering Division. "This is comparable to the kinetic energy of a superfast train, like Europe's TGVs, launched at 1,500 to 1,700 kilometres per hour ..."

In case of a "quench"—a rare but anticipated event that causes the magnet system to lose superconductivity—this huge amount of stored energy needs to be "liberated" in a matter of seconds.

The fast discharge units have a powerful switching system that opens a new path for this stored energy—a veritable "boulevard" along which this energy is transferred into a set of massive resistors located in a nearby building. There, the energy is dissipated in the form of heat.

The reliability of the fast discharge units is of utmost importance for the safeguard of the magnet system," adds Ivone. "That is why we'll have a backup system in the form of an explosive charge, that instantly 'cuts the circuit' and transfers the stored energy to the discharge resistors."

Preparing for the installation phase: specialists from the ITER Organization, the Korean, Chinese and Russian Domestic Agencies, and the industries involved gathered for a two-day workshop at ITER Headquarters.

Like all constructions on the ITER platform (with the exception of the Cryostat Workshop) the Magnet Power Conversion Buildings are part of Europe's contribution to the project.

Procurement responsibility for the equipment in the buildings is shared by Korea (18 converter units and one master control system), China (14 converter units) and Russia (fast discharge units and some 2.5 kilometres of busbars for a total weight of 350 tonnes).

At the end of the year 60 to 100 workers (technicians from the Korean and Chinese Domestic Agencies plus contractors) will begin installing the equipment.

Last week, specialists from the ITER Organization, the procuring Domestic Agencies, and industry met at ITER Headquarters to discuss what Ivone calls "cohabitation during installation works."

"It is important at this stage to sort out respective responsibilities, and discuss installation sequences, onsite installation management, the details of finishing operations, and a host of other practical issues ..."

Just like plugging the adapter into the socket—with a bit of added ITER complexity.