Image of the week

Hooked!

23 Oct 2017

Big, powerful cranes need big, powerful hooks.

The hook pictured in this image is one of four that belong to the double overhead bridge crane installed 43 metres above the floor in the Assembly Hall.

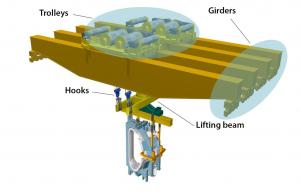

The double crane is made of two pairs of girders and corresponding trolleys (see diagram). The hooks are attached below by two redundant cables wound eight times in a pulley block.

Each hook has a lifting capacity of 375 tonnes.

Behind the blue hook in the photo is the yellow lifting beam (see diagram) that will be used to manoeuvre the heaviest machine components such as the vacuum vessel sector assemblies or the central solenoid.

The "1385 t" that we see mentioned refers to the operational lifting capacity of the whole system (1,500 tonnes) minus the dead load of the lifting beam.

Lifting tests with dummy loads (1,875 tonnes) are scheduled in December.