Cryoplant

How to install a compressor

20 Nov 2017

In order to properly install a helium compressor skid on its concrete pad, you need to start with a large push broom to sweep away the dust that inevitably accumulates on the pad's surface.

The last of the 18 skids will be safely and precisely installed atop their massive four-metre-high concrete pads this week.

Then come sophisticated laser measurements; a set of steel plates, or shims, of different thicknesses; and, eventually, a powerful telescopic crane to delicately manoeuvre the 20-tonne compressor skid into place.

In the ITER cryoplant, the last of the 18 skids will be safely and precisely installed atop their massive four-metre-high concrete pads this week. Organized in three "compression station trains," each linked to a helium cold box, the compressors will supply the cold boxes with gaseous helium at 21.8 bars and eventually provide the necessary gas flow for the supercritical helium cooling needs of the Tokamak.

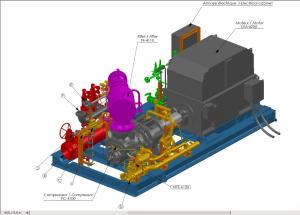

The 20-tonne skid comprises the compressor itself, its motor, and different auxiliaries. Perfect positioning is essential to avoid vibrations and difficulties in attaching the interconnections of the "station trains."

Positioning the 20-tonne skid—which comprises the compressor itself, its motor, and different auxiliaries—onto the surface of the concrete pad is an operation that demands millimetric precision, as a slight misalignment could result in damaging vibrations and difficulties in attaching the interconnections of the "station trains."

A pad's concrete surface, however, cannot provide the perfect reference for such tight tolerances. Tiny differences in "altitude" or planarity brought to light by laser measurements need to be compensated by the stacking of shims upon which the skid will rest.

And then the final step: once the skid is in place and anchored deep into the pad's slots, a special grouting—part cement, part resin—is poured to federate the pad and the skid into a mechanically homogeneous structure—a monolith of concrete and steel.