Open Door Day

An awe-inspiring experience

28 May 2018

-

ITER Communication

In one of the videos on a continuous loop in the ITER Visitors Centre, Director-General Bernard Bigot introduces the fundamentals of fusion energy by saying: "The principle is simple..."

Vincenzo Sarica, from European contractor Engage, was one of the 50 volunteers on hand to tell the ITER story. In this case, he is directing gazes upward as he describes the 30-metre-tall "well" that was built to house the ITER machine.

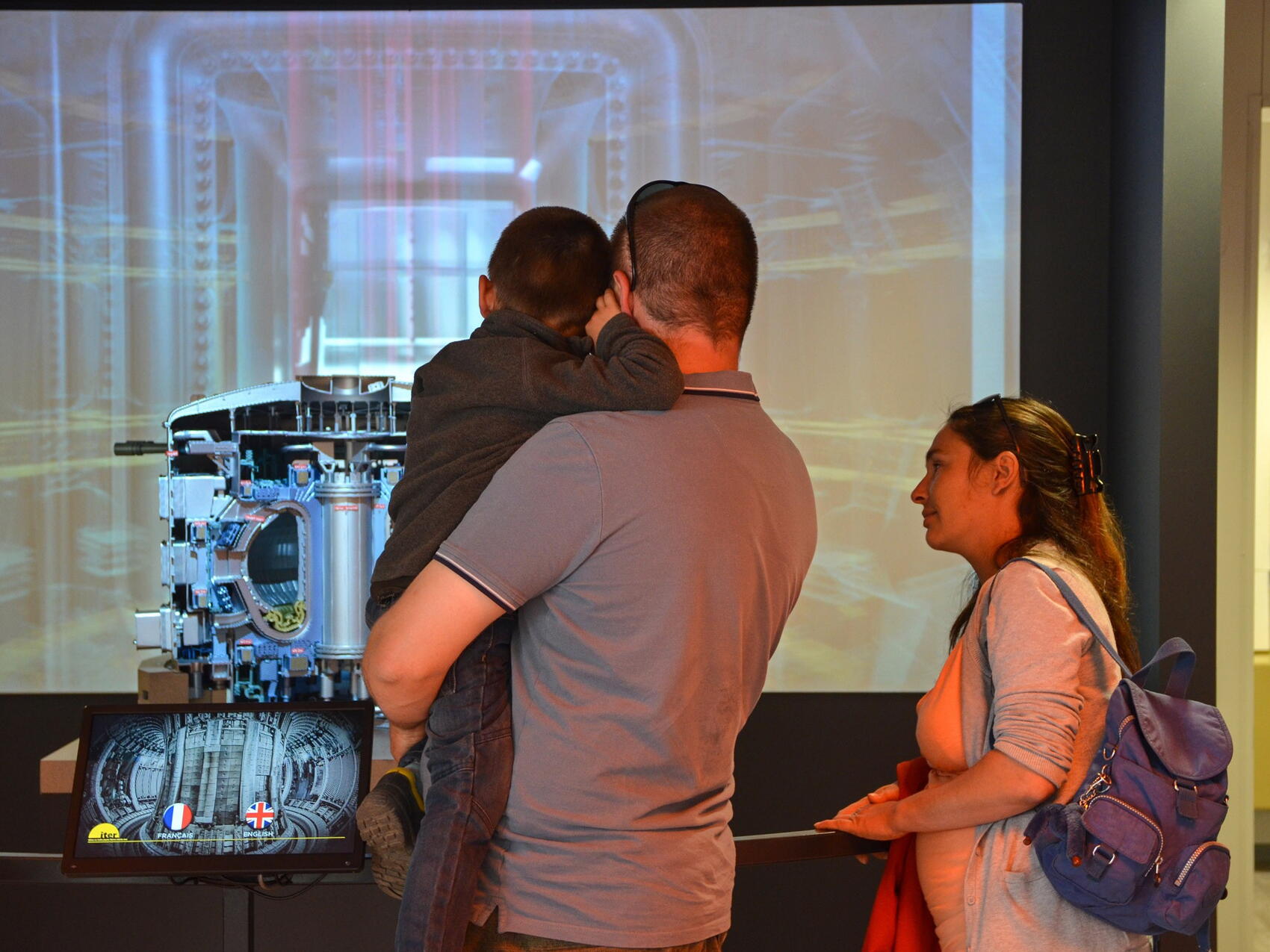

On Saturday, as ITER's doors were opened wide to staff, families and the general public, some 700 visitors were offered a unique opportunity to see the simplicity of the principle—and the massive complexity of its implementation—for themselves.

DIFFER, the Dutch Institute for Fundamental Energy Research, had brought to ITER its Fusion Road Show—a stage-magic-style operation that explains plasmas and magnetic confinement using props like a microwave oven, a horseshoe magnet, a smoke box, matches and neon tubes.

Brilliant, simple and fun, the show made a perfect introduction for what was to follow: a worksite tour that included a unique opportunity to view the ongoing operations in the Assembly Hall and, even more exceptional, a descent into the Holy of Holies of the ITER installation—the basement level of the bioshield where machine assembly will soon begin.

With the "simple principles" fresh in their mind, the visitors could now take in the sheer size of what it takes to turn them into reality. They had all seen ITER from afar, driving up and down the thruway or along the country road between the villages of Saint-Paul-lez-Durance and Vinon-sur-Verdon. Now, they were inside the project's most emblematic structure. And they could barely believe how massive, tall and unique it was.

At every stage of the visit, volunteers from the ITER Organization, the European Domestic Agency and from Europe's contractors Engage, Energhia and Apave provided the necessary explanations on the whys and hows of the project, answering thousands of questions and sharing their enthusiasm for this potentially world-changing venture.

Saturday was the 12th edition of the ITER Open Doors Day. And like all editions since 2012, it was a moment of awe and wonder for the visitors.