Manufacturing in China

A set of clamps to resist all loads

18 Jun 2018

-

ITER China

China is providing an extensive array of supports and clamps for ITER's superconducting magnet systems—in all, more than 1,600 tonnes of equipment. On 9 June, the first batch of U-shaped poloidal field clamps was on display, ready for shipment to ITER.

The U-shaped clamps will be spaced regularly around ITER's fifth poloidal field magnet coil (PF5), which is now under construction at ITER by contractors to the European Domestic Agency. The clamps weigh about 3.5 tonnes each.

Eighteen poloidal field magnet clamps—3.5 tonnes each—stand in orderly rows at Guizhou Aerospace Xinli Casting & Forging Co., Ltd. (HTXL) in Zunyi, Guizhou Province, China.

These first-completed coil clamps will be sent to the European magnet winding facility at ITER, where they will be mounted directly on poloidal field coil #5 (PF5) at the end of the fabrication sequence. Spaced at equal distances around the superconducting winding pack, the role of the clamps is to support the weight of the coil (just under 350 tonnes) as well as to withstand the thermal loads during the cooling of the magnets and the alternating electromagnetic forces from the different magnet coils during the operation of the Tokamak.

Representatives of the ITER Organization, the Chinese Domestic Agency, and main contractor SWIP (Southwestern Institute of Physics) were on site at HTXL to celebrate the completion of the first batch in a long series of magnet support components that must be completed within the next few years.

ITER's six poloidal field coils all require U-shaped clamps, but due to differences in coil width and height, not all the clamps are the same. During the initial qualification phase from 2010 to 2014, the main contractor to the Chinese Domestic Agency, SWIP (Southwestern Institute of Physics), asked three subcontractors to realize prototype clamps for poloidal field coil PF2, whose design is very similar to those needed for PF5.

The most challenging manufacturing step for these three suppliers was the creation of a deep, but narrow slot on each "leg" of the U-shaped clamps (see the top photo in this article). These apertures are designed to ensure the strength and flexibility of the component, however at just 20 mm in width (+/-3 mm) for a slot as deep as 1 metre they are difficult to realize without introducing deformation or defect. Two of the suppliers relied on welding machined plates together to create these slots, but were unsuccessful in reaching the required technical specifications on their prototypes. A third, HTXL, devised an innovative solution that was successful.

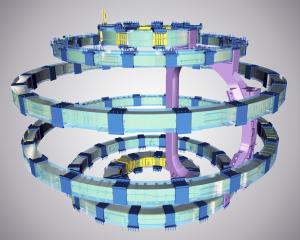

The poloidal field coil clamps, visible in dark blue, are designed to support heavy loads as well as weather the significant stress and force related to thermal expansion and electromagnetic loads.

HTXL developed a creative forging and wire cutting technique that avoided welding-induced deformation while achieving strict dimensional tolerances and maintaining the excellent mechanical properties of the high-grade steel material. In the HTXL solution, a circular piece of metal is first forged around a clamp-shaped mold and then cut into two U-shaped forgings. Deep-hole drilling and wire-cutting is used to create the deep slots in the thick side plates, before the final products are machined to the required dimensions.

The full scope of the magnet support Procurement Arrangement signed by China includes 18 toroidal field coil gravity supports; 18 coil clamps each for PF2, PF3, PF4 and PF5; 9 coil clamps each for PF1 and PF6; and supports for all 18 correction coils—more than 1,600 tonnes of equipment in all. As some of the first equipment needed on site for installation in the Tokamak Building, the on-time delivery of the material is particularly important.

Now, once final documentation is completed, the full set of 18 poloidal field coil clamps produced at HTXL will be shipped to the ITER site. Also included in the first shipment is the first toroidal field gravity support, and the first-of-series clamp supports for PF3 and PF4.

The full scope of the magnet support Procurement Arrangement signed by China includes 18 toroidal field coil gravity supports; 18 coil clamps each for PF2, PF3, PF4 and PF5; 9 coil clamps each for PF1 and PF6; and supports for all 18 correction coils—more than 1,600 tonnes of equipment in all. As some of the first equipment needed on site for installation in the Tokamak Building, the on-time delivery of the material is particularly important.