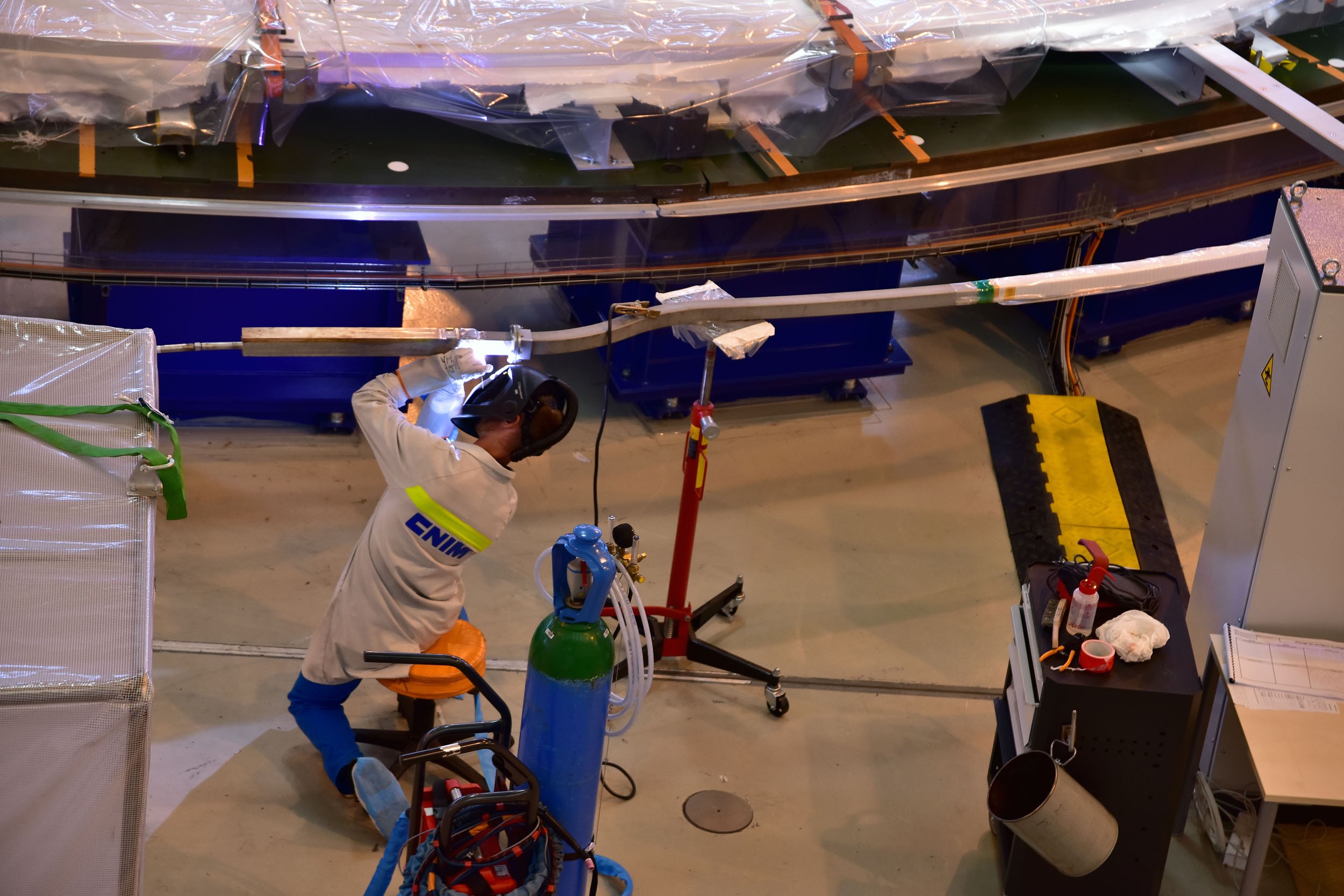

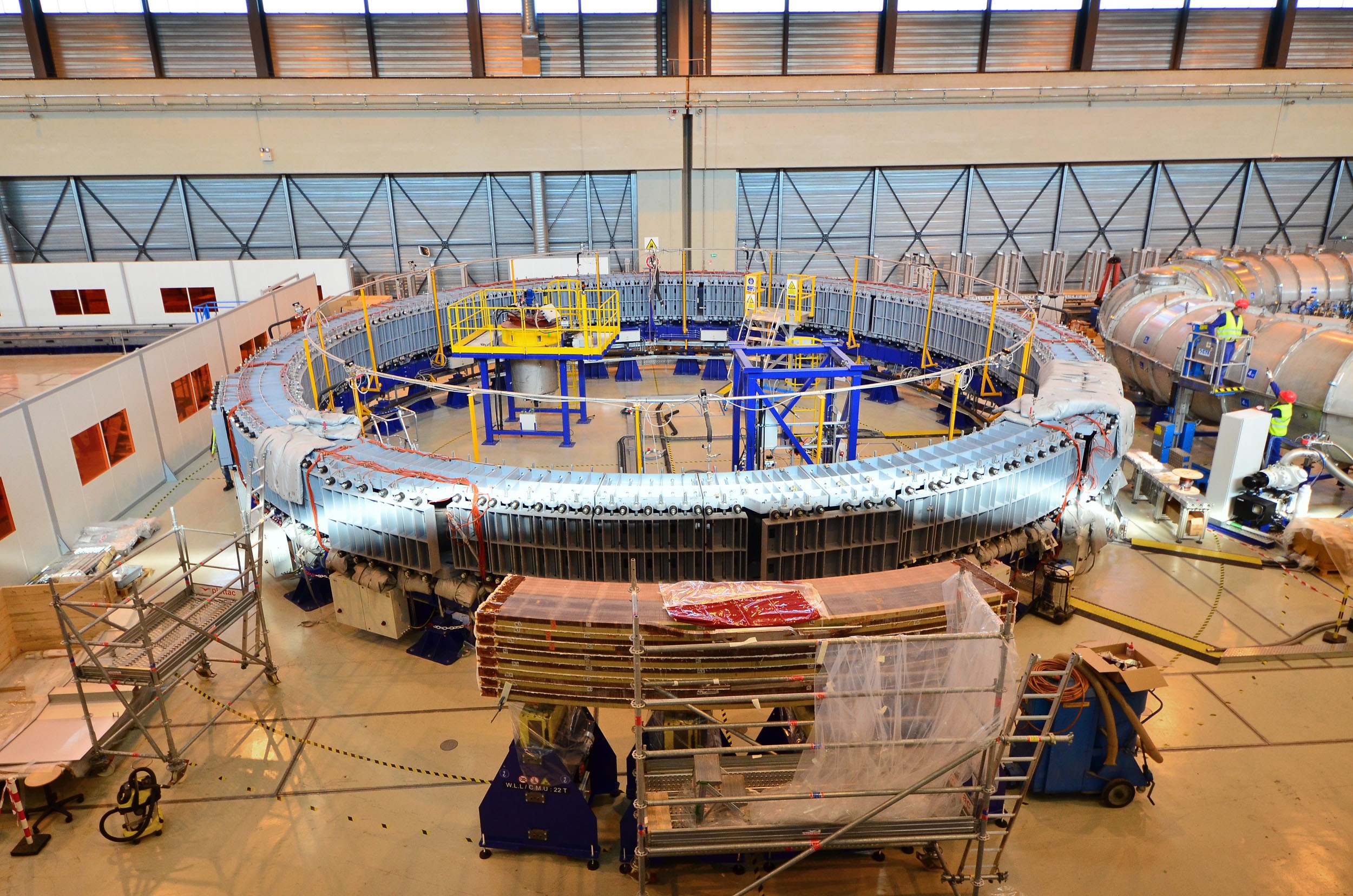

Ring magnet fabrication in full swing

At least as wide as a five-lane highway, ITER's largest ring-shaped magnets are too big to be transported in their finished state. The European Domestic Agency has purpose built a facility at ITER to house their fabrication only a few hundred metres from machine assembly pit. This report will take you inside the building, where a team of 70 is advancing the fabrication of the first production unit—poloidal field coil #5 (PF5).