Sector sub-assembly

Twin meets twin

15 Oct 2018

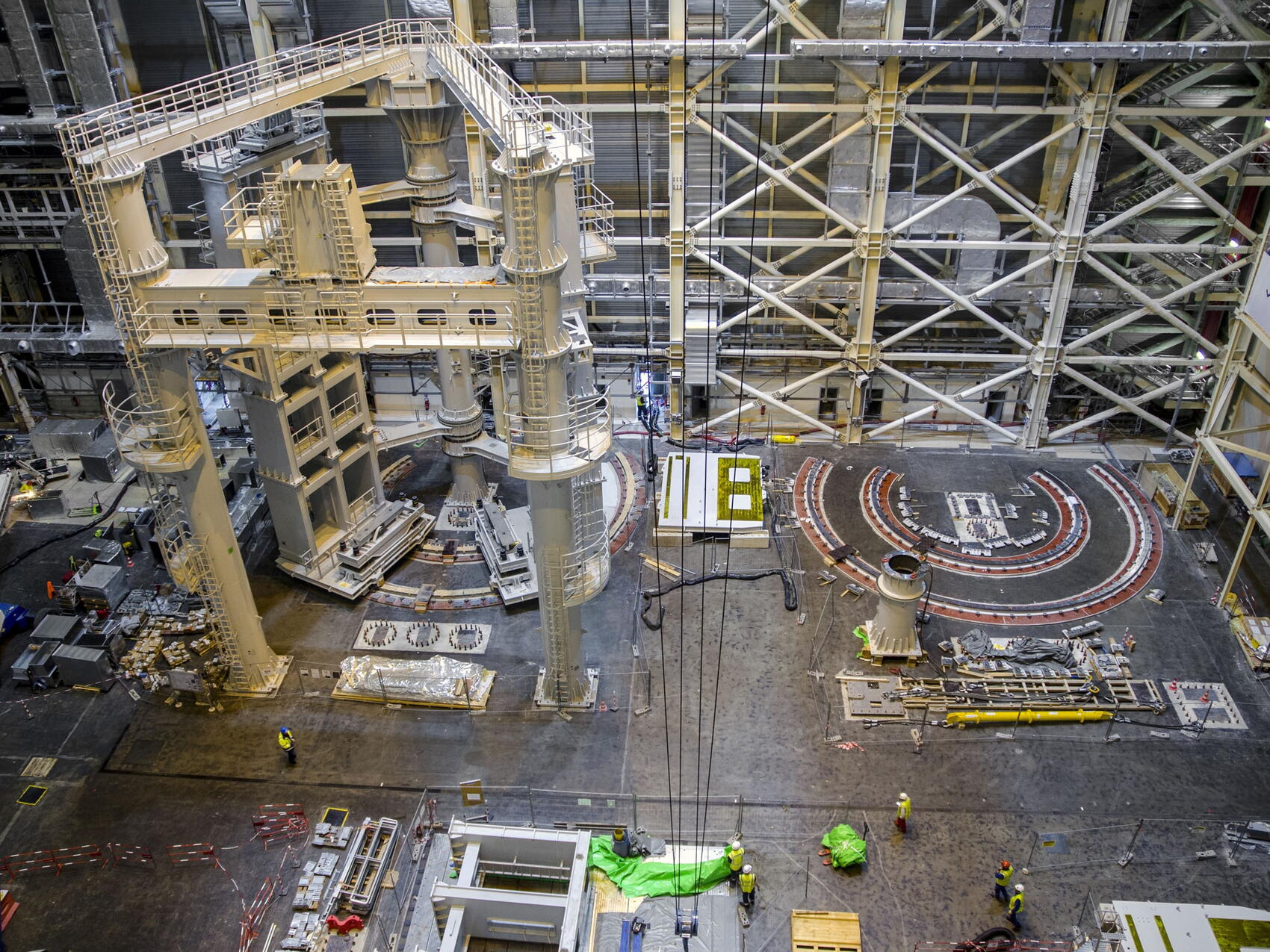

Although they were born one full year apart, they are identical twins: when the second vacuum vessel sector sub-assembly tool (SSAT-2) is complete, nothing will distinguish it from its sibling.

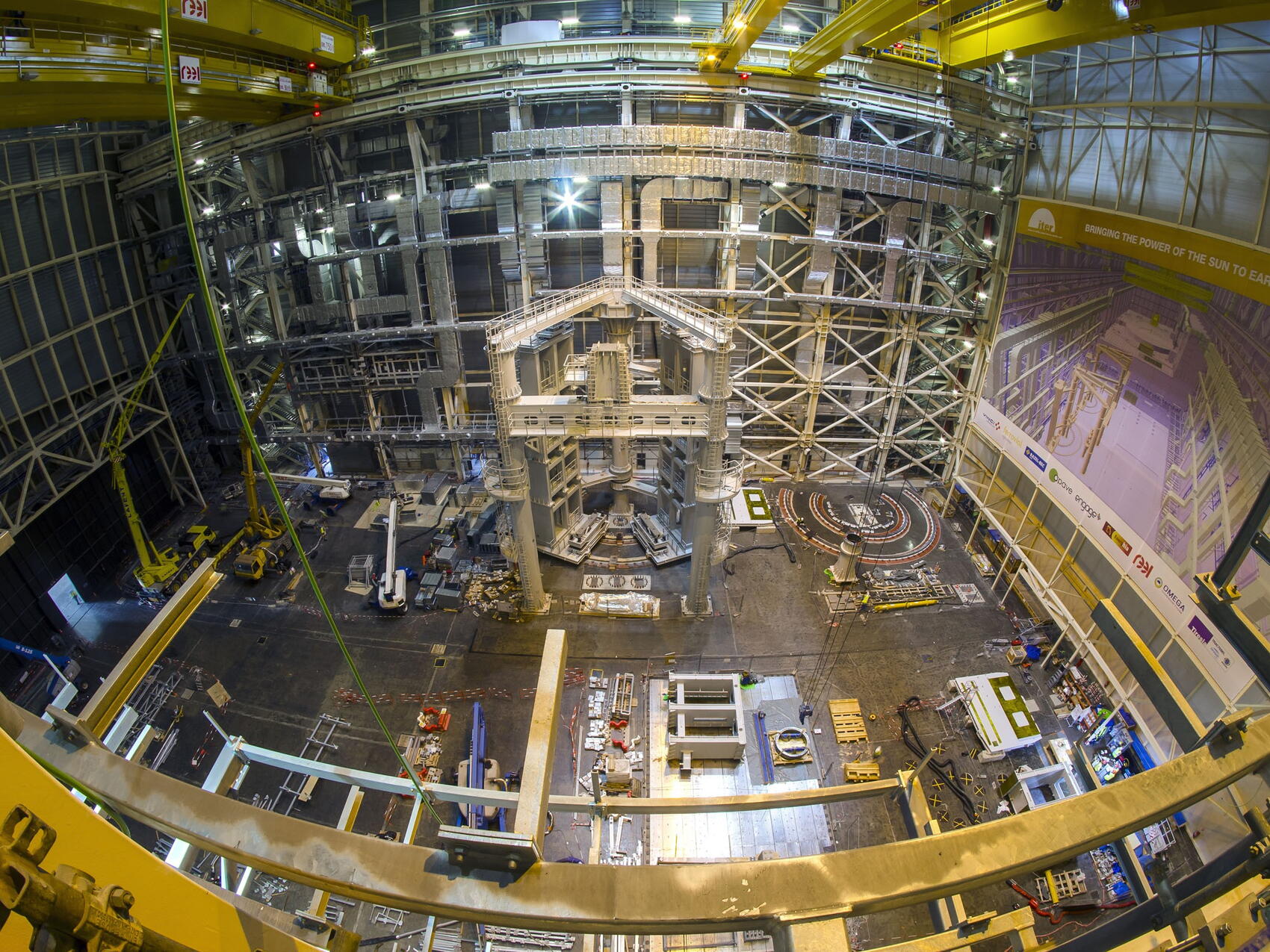

Powerhouse: this 800-tonne tool stands 22 metres tall and can handle a 1,200-tonne subassembly. And it will soon have an identical twin in the Assembly Hall ...

In the vast and resounding Assembly Hall, the first sub-assembly tool is a towering presence: the mechanical structures have all been assembled and work on electrical and hydraulic connexions will soon proceed.

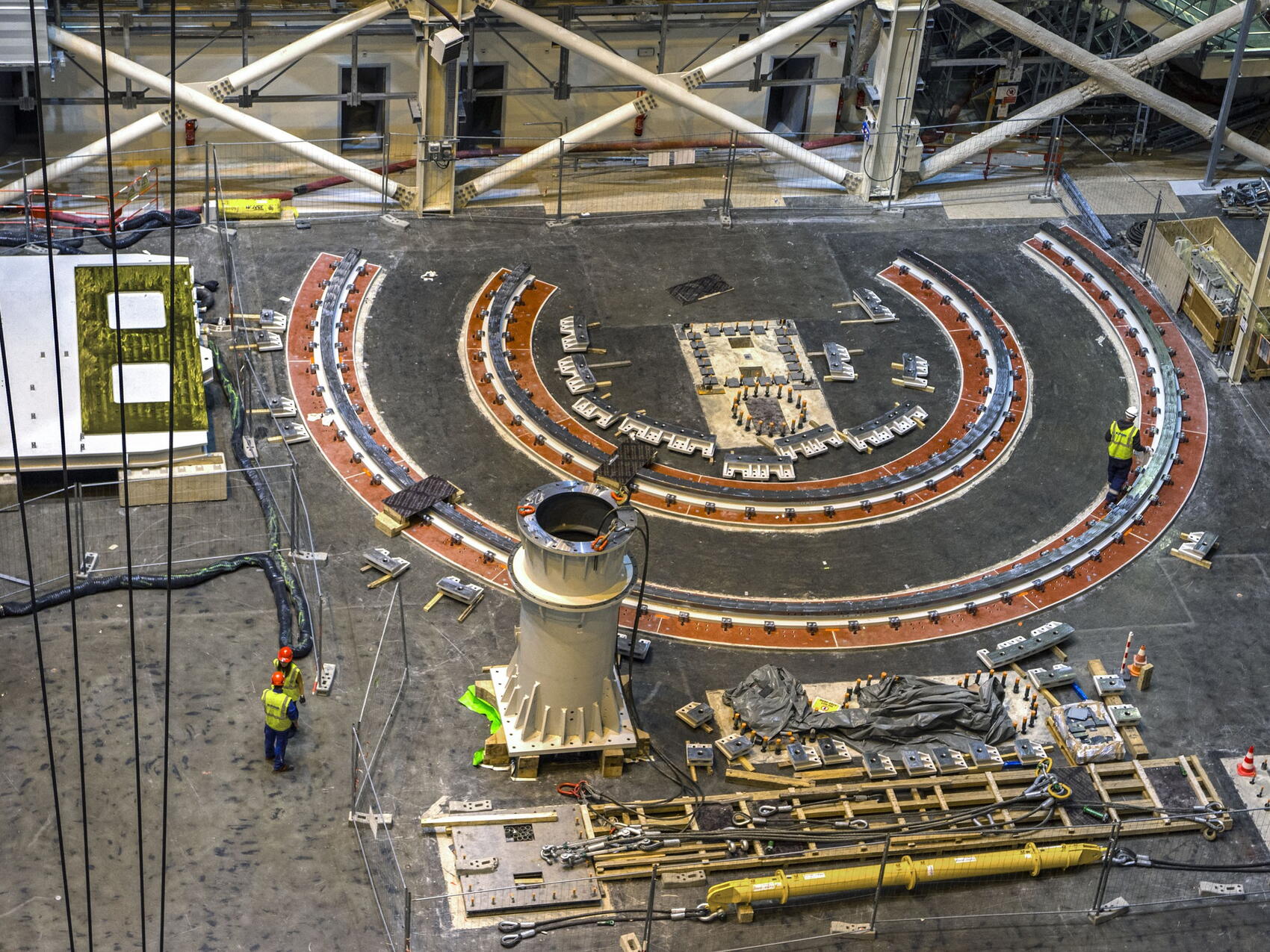

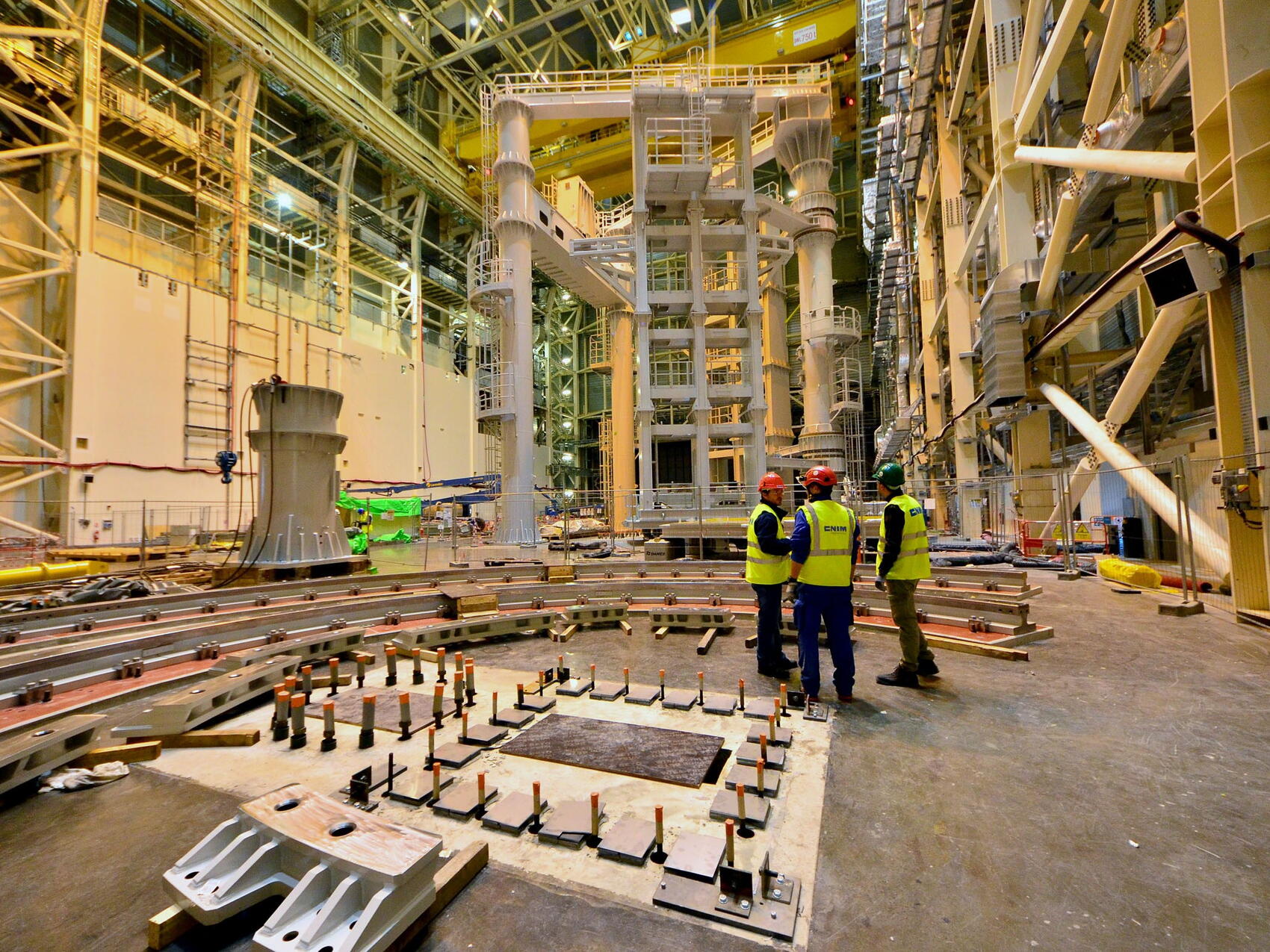

SSAT-2, by contrast, is just hatching—four batches of components, out of a total of six, have been delivered by Korea to the ITER site. Specialists from the French contractor CNIM are busy installing and precisely aligning the toroidal rail tracks upon which the wings of the giant tool will travel, and the first leg segment has been brought in for installation.

Full assembly of the second vacuum vessel sub-assembly tool should be complete by the end of January 2019.

For more pictures and details, check the gallery below.