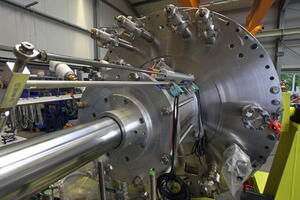

According to Robert Pearce, ITER Vacuum Section leader, the design of the ITER cryopumps design has been an engineering challenge due to their operation at both cryogenic temperatures (<4.5 K) and high temperatures (up to 500 K); the precision needed on the moving parts on the

world's largest all-metal high vacuum valve; and their core importance to the reliable operation of ITER. "Not only did the pumps have to be designed, but the manufacturing of many of the parts had to be tested. The manufacturing of the pre-production cryopump (delivered to the ITER site in

August 2017) paved the way for a successful final design review in March 2018."

This milestone has been achieved due to a strong collaboration between the ITER Organization and the European Domestic Agency, and has involved many actors including European industry and associations.

"Signing this Procurement Arrangement allows the call for tender to be released to manufacture the eight cryopumps," explain the technical officers for the procurement, ITER's Matthias Dremel and Fusion for Energy's Francina Canadell. "ITER will continue its collaboration throughout the manufacturing phase and this shall ensure delivery of the pumps to the ITER site in 2023 for installation in the divertor ports of the vacuum vessel and cryostat. These components are critical to achieving the vacuum necessary to initiate First Plasma in 2025."