Insertion is a success

The first superconducting winding pack made in Europe for ITER's D-shaped toroidal field coils is now ensconced in its 200-tonne protective case. The first-of-a-kind insertion operation was carried out successfully at SIMIC, in northern Italy.

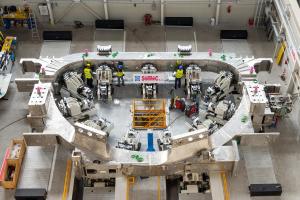

On the insertion rig at SIMIC, the 110-tonne winding pack is laid out flat. On either side, the two halves of the steel coil case—the straight inboard segment and the D-shaped outboard segment—have been positioned at the same height. Working within tolerances of 0.2 mm, the insertion tooling slowly brings the "pieces" together and the winding pack disappears inside the heavy steel case.

Under the contract with SIMIC, winding packs shipped from ASG are cold tested at -193 degrees Celsius (80 K) using a combined cycle of nitrogen and helium. Insertion into the steel structural case comes next, in an operation requiring sophisticated laser dimensional control technology and complex tooling in order to move and fit components weighing hundreds of tonnes with millimetre-level precision. Finally the interior cover plates will be attached and welded in compliance with stringent standards. The thickness of the welds (up to 130 mm) and the fact that welding will have to be carried out from one side only adds to the challenge of this final operation.