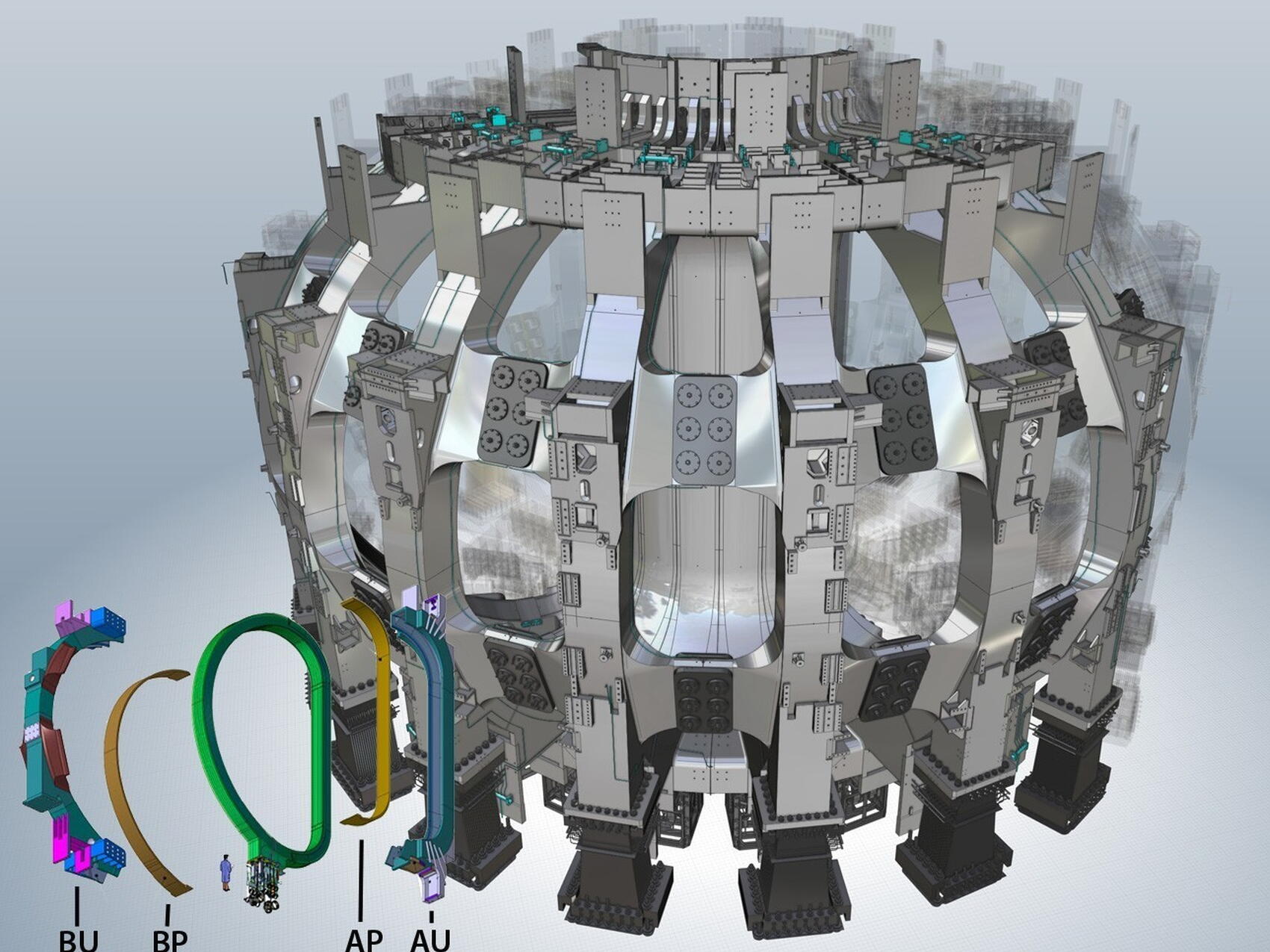

The outboard leg was contracted by Japan to Hyundai Heavy Industries in Ulsan, Korea. The ultimate test was then to verify that structures manufactured in two locations following stringent ITER Organization specifications would fit together perfectly. "Ultimately, the story of the toroidal field coil cases is the occasion to showcase the spirit that underlies the ITER Project in its entirety—the "One-ITER" spirit of teamwork that unites us around one design, one schedule and one mission," stressed Deputy Director-General Tada.

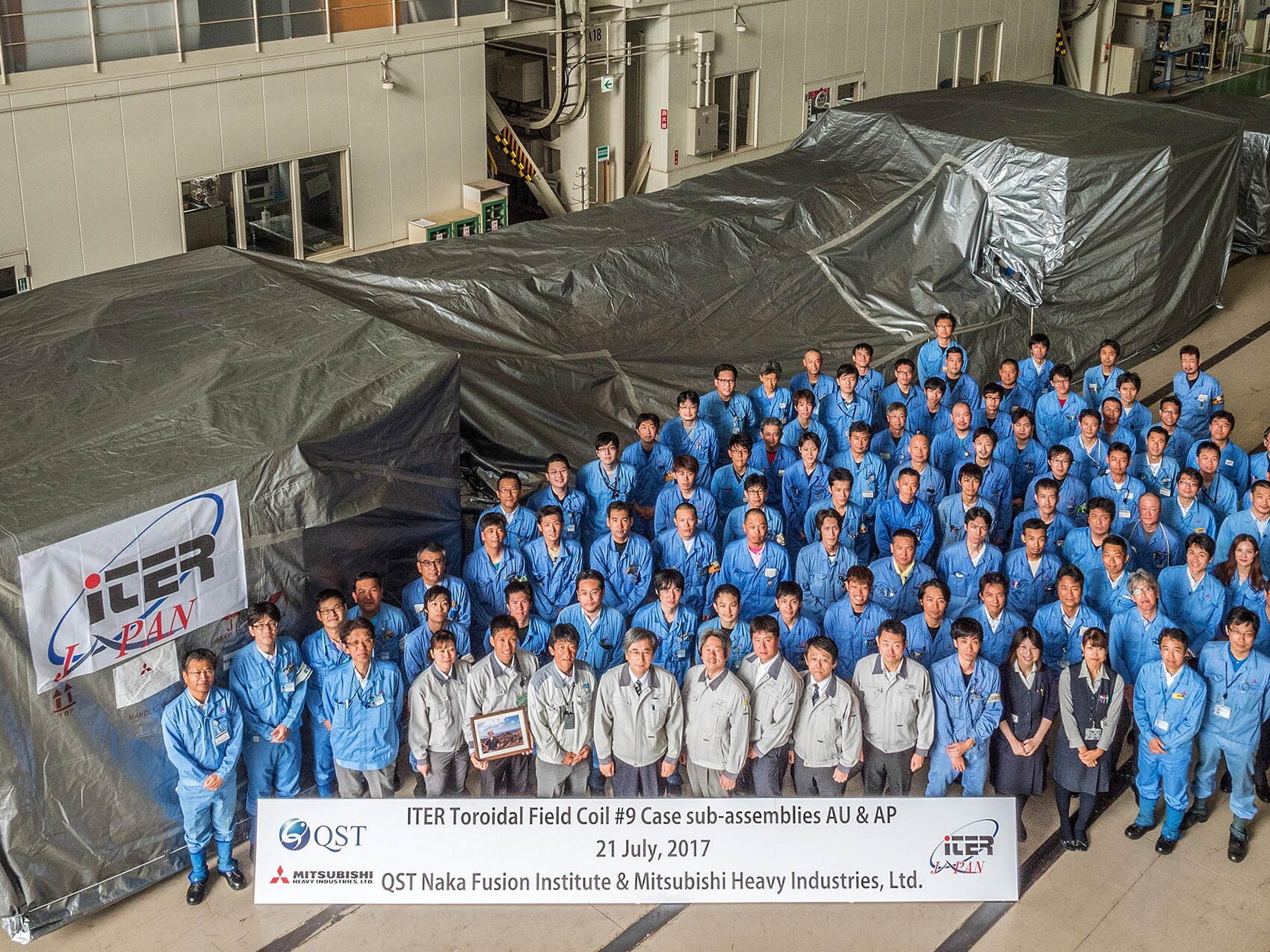

At Hyundai, the outboard leg sub-assemblies ("BU" and "BP") were first fitted together to verify manufacturing precision. Then, on 18 and 19 December the principal segments of the coil case ("AU," manufactured in Japan and shipped to Korea, and "BU" manufactured in Korea) were positioned and measured. (Please see the photo gallery below for further explanations.)

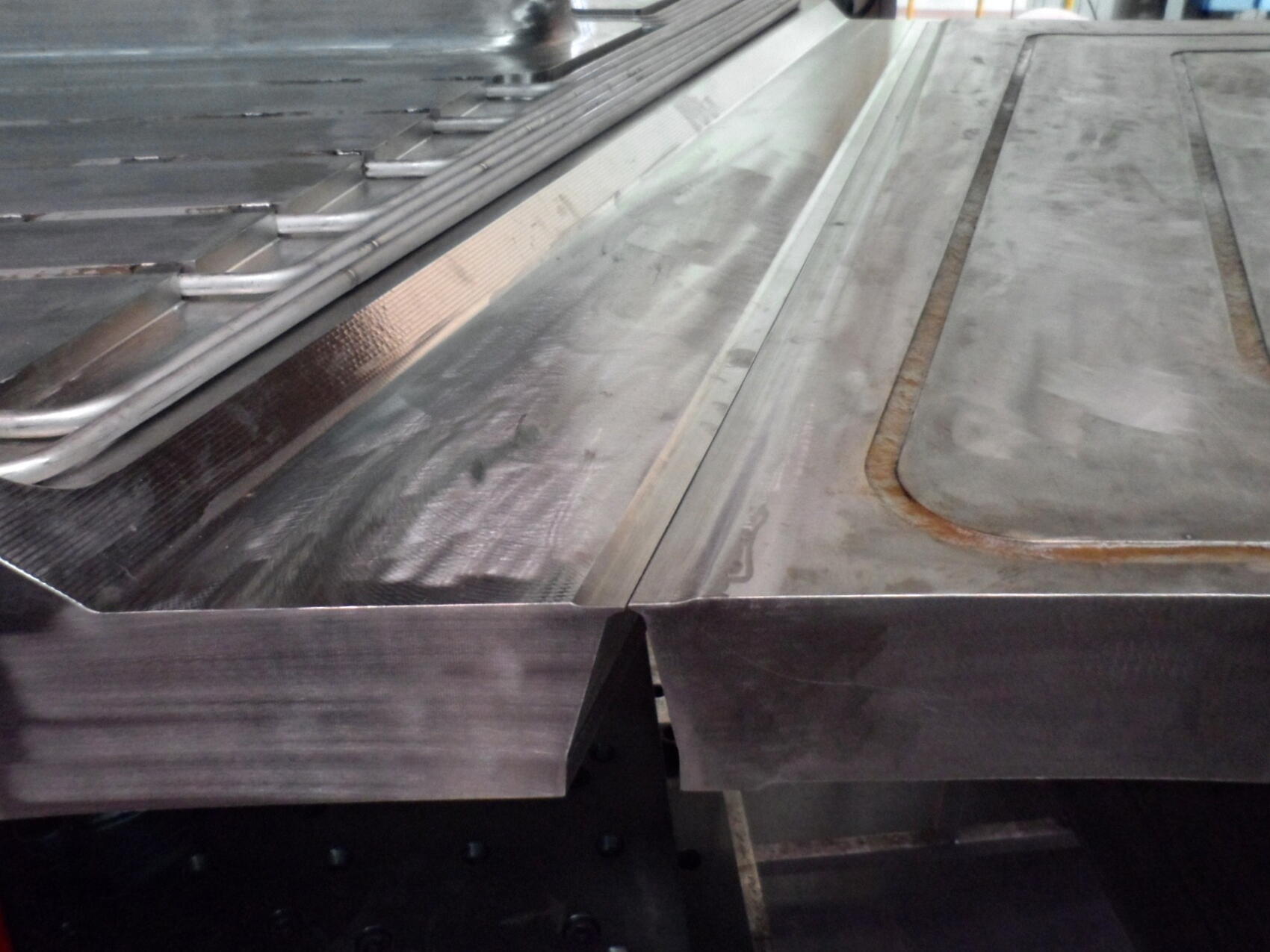

The required tolerances of bevels at the welding grooves were respected across the board at less than 1 millimetre—with gap variations ranging from 0.25 mm to 0.75 mm. Witnesses on hand during the fitting tests included representatives of the ITER Organization, the Japanese and Korean Domestic Agencies, the European Domestic Agency (which will be receiving the component), and manufacturers Mitsubishi Heavy Industries and Hyundai Heavy Industries.

The successful fitting trials of the first toroidal field coil case demonstrates that the final assembly—the insertion of the superconducting winding pack followed by closure welding—can be achieved within the tight tolerances required. This is excellent news, as work proceeds on the fabrication and precision machining of elements for the other 18 cases.

The first case is now on its way to SIMIC (Italy), where the first European winding pack

has been delivered for insertion.

*QST—Japan's National Institutes for Quantum and Radiological Science and Technology—is responsible for the procurement of all components allocated to Japan by the ITER Organization.