Right in the line of the beam

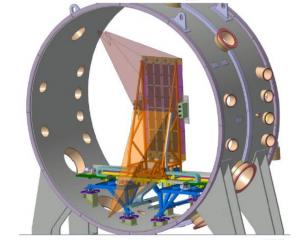

To fully intercept the SPIDER beam—which occupies approximately one square metre—16 carbon fibre composite tiles are needed. The tiles are kept in place by a metallic structure whose position can be remotely controlled in order to diagnose the beam at different distances from the source. The structure is also equipped with electrostatic sensors and thermocouples to provide additional information.

Even if the tiles are capable of sustaining temperatures in excess of 1,000 ˚C, they cannot withstand the full power (up to 6 MW) of the SPIDER beam for long periods; hence, for long pulses, the metallic structure of STRIKE opens to allow the beam to pass through and be intercepted further along by an alternative calorimeter, the actively cooled "beam dump."