A clamp with added cooling

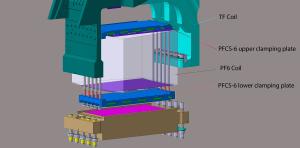

The nine clamps around ITER's bottom-most poloidal field coil (PF#6) will be equipped with integrated cooling to remove the heat deposited in the poloidal field supports before it is conducted to the coil. Meticulous trials and qualification tests have led to the successful fabrication of the first unit in China.

On 1 March, the first pair of support clamps for poloidal field coil #6 was turned over by the Chinese Domestic Agency to Fusion for Energy, the European Domestic Agency responsible for delivering PF#6 to ITER.

One upper clamp and one lower clamp—the first pair out of nine that are required—has officially passed all receiving inspection and acceptance tests and will be delivered to the Chinese institute ASIPP, which is producing PF6 under an agreement signed with Europe. Parallel to this successful milestone, manufacturers SWIP and Sichuan Jingcheng Energy Equipment Co. Ltd. (JCNY) are producing the eight other sets in series.

One of the most challenging aspects of manufacturing these components is the cooling system that must be integrated inside the clamping plates. The cooling system serves as a thermal shield between the base clamps and the coil by removing the heat deposited in the poloidal field supports before it can be conducted to the coil. Helium leak tests carried out late last year were the final inspection step guaranteeing quality before delivery.

The nine support clamps will be mounted on the PF6 coil at ASIPP by means of pre-tensioned tie-rods.

Under the scope of the Magnet Support Procurement Arrangement signed with the ITER Organization, the Chinese Domestic Agency is procuring 18 toroidal field coil gravity supports; 18 coil clamps each for PF2, PF3, PF4 and PF5; 9 coil clamps each for PF1 and PF6; and supports for all correction coils—more than 1,600 tonnes of equipment in all.