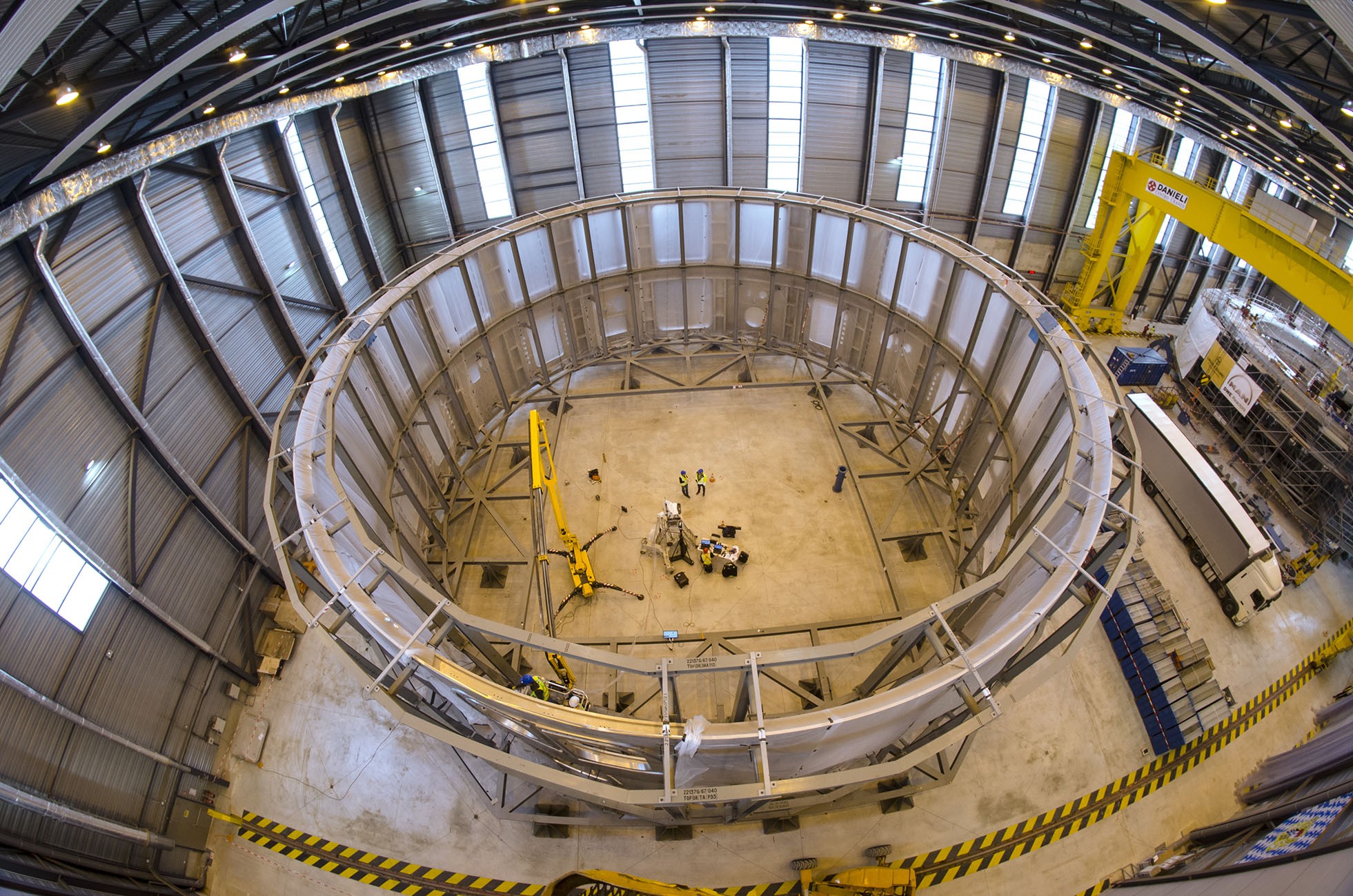

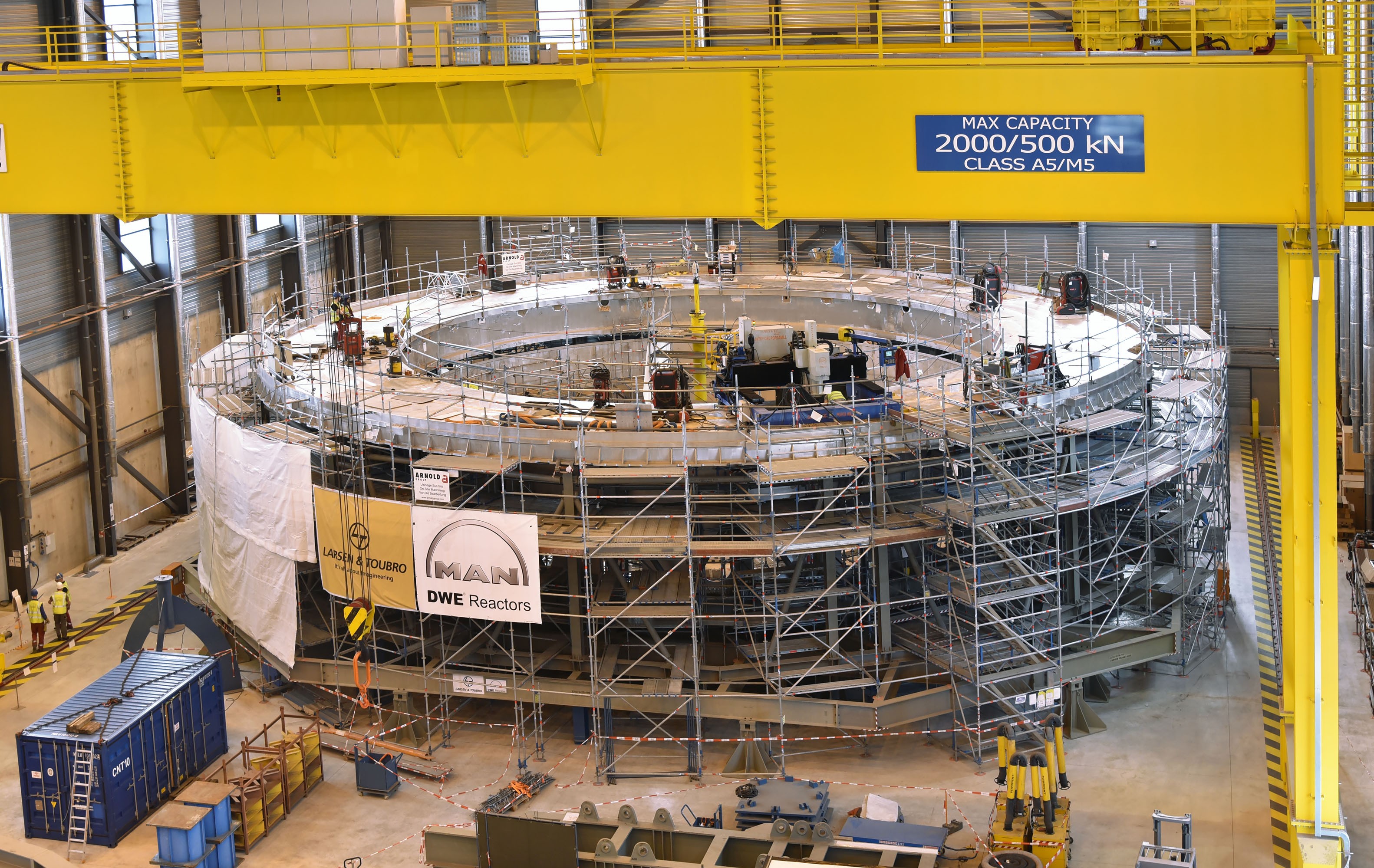

Lower cylinder revealed

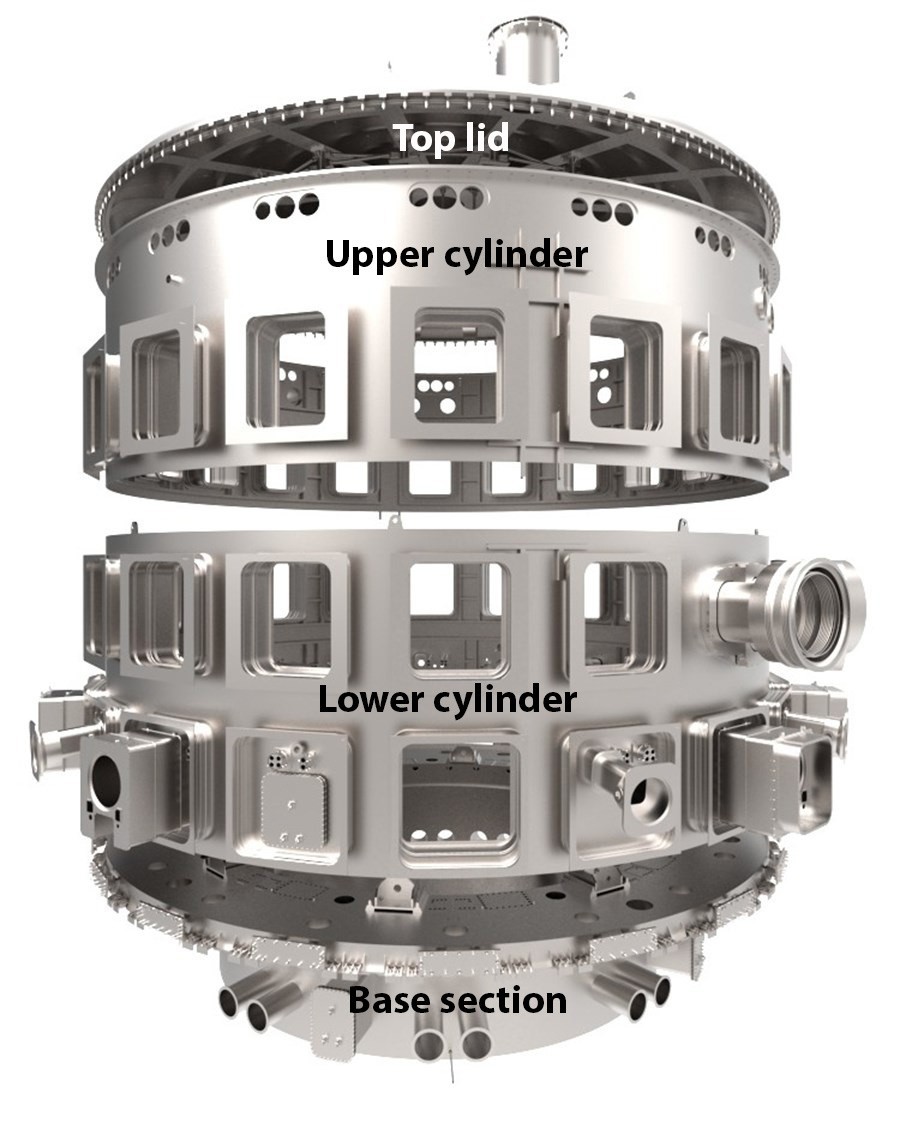

They were all there: those who designed it, those who forged it, those who assembled and welded it, and those who closely monitored the requirements and procedures connected with a "safety important" component. Two years after an array of segments were delivered to ITER, the cryostat lower cylinder—one of the four sections that form the giant thermos that will enclose the machine — had been fully assembled. With scaffolding removed and just a thin translucent film to protect it, the massive structure was at last revealed, both delicate and mighty.