Fabrication begins on unique composite rings

After lengthy development, prototyping and test phases, the composite rings designed to help ITER's toroidal field coils cope with huge out-of-plane forces have been cleared for fabrication.

In ITER, the electromagnetic interaction between the toroidal field coil current and the magnetic field generated by the poloidal field coils will create huge stresses on the toroidal field coils. Pre-compression rings will be installed at the top and bottom of the coil structures to "push back" with a centripetal force of thousands of tonnes, suppressing any deflection and greatly reducing cyclic fatigue stresses.

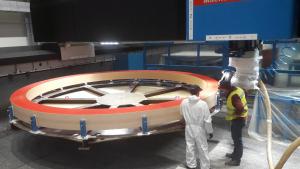

CNIM has partnered with Exel Composites (Finland) for the raw material—a pultruded laminate delivered in lengths of 2.8 km (2 mm thick) on spools. Each laminate profile is wound into one ring on specialized winding tooling, with alternate layers of 0.12 mm-thick epoxy tape applied. The completed ring is cured and then machined to the required final dimensions.