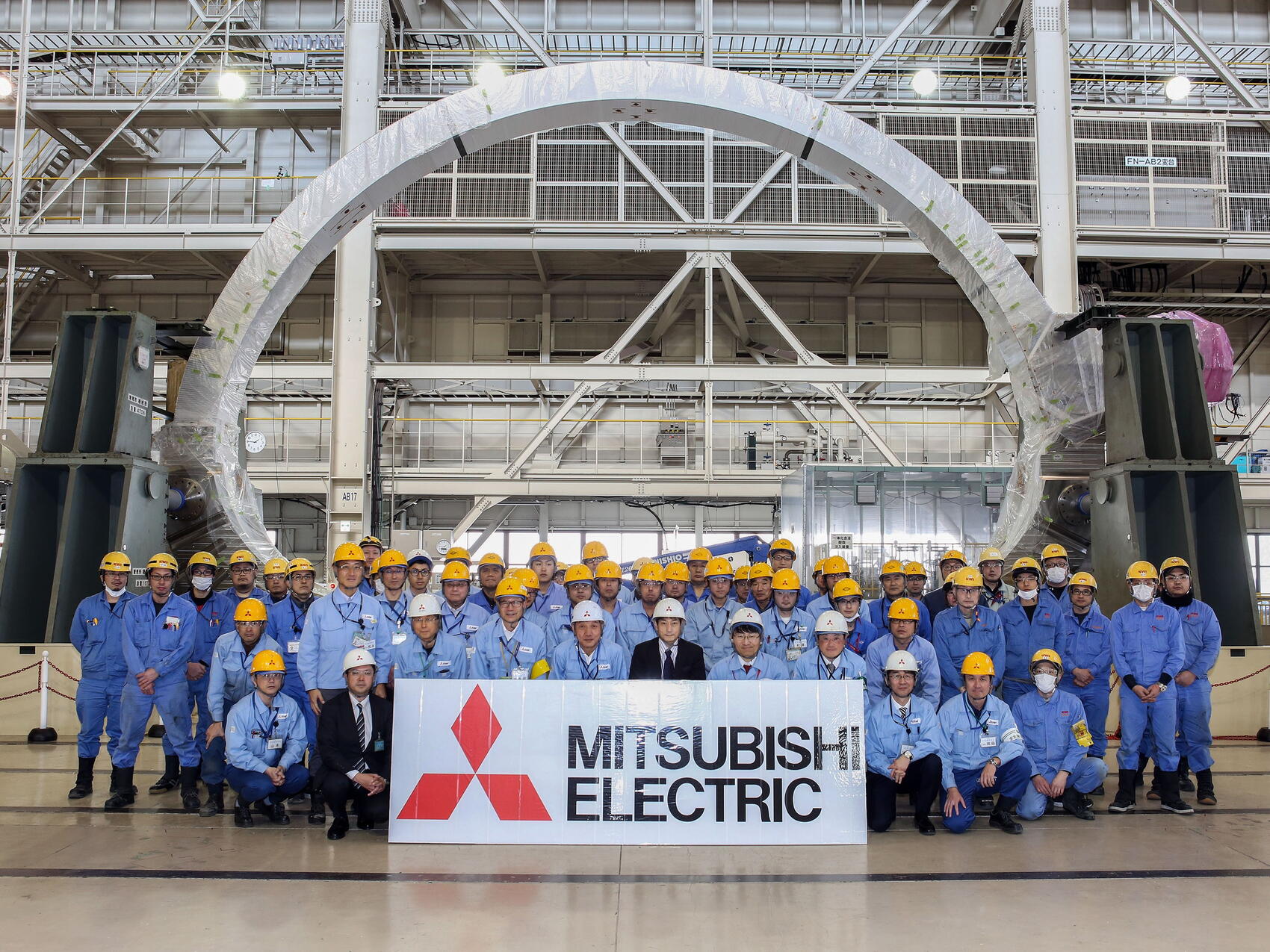

"I am deeply honoured to be here with you to celebrate the completion of this first-of-a-kind component," said ITER Director-General Bernard Bigot during the event held at Mitsubishi Heavy Industries' Futami plant in Hyogo Prefecture, Japan. "As you know [this coil has been] years in design, procurement, production and testing. Congratulations to all who contributed to this major technical and human achievement!"

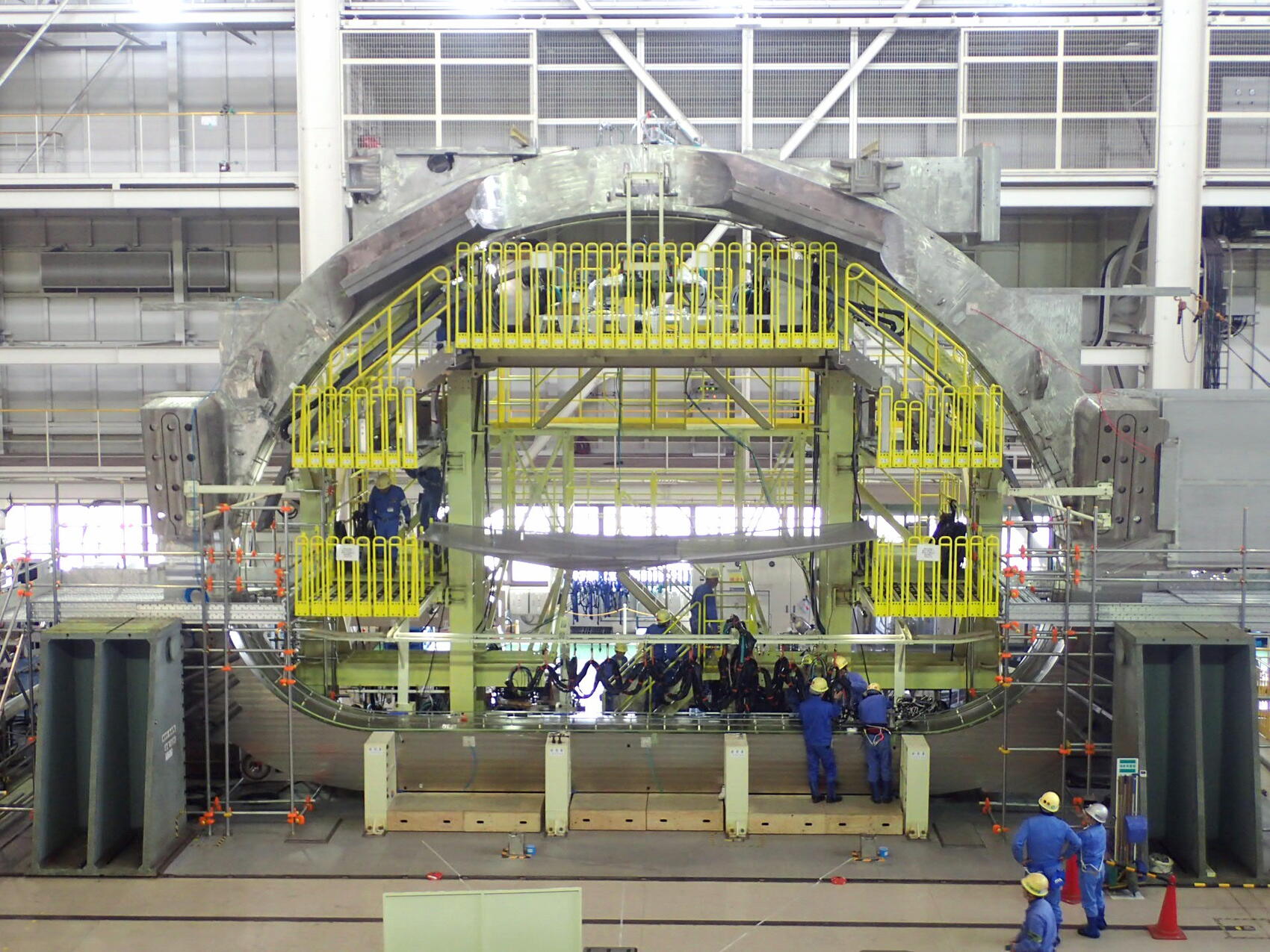

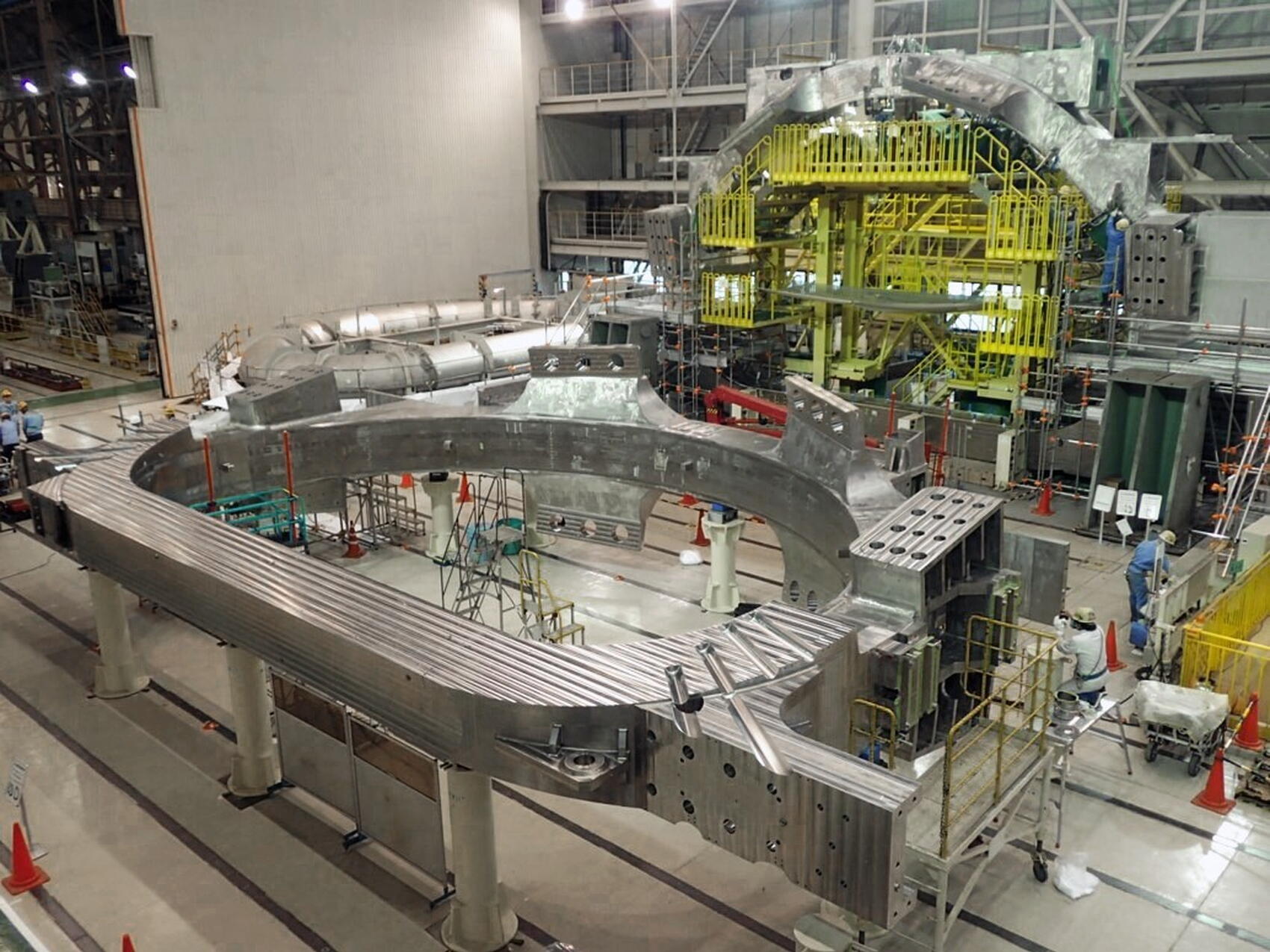

Eighteen "D"-shaped toroidal field magnets placed around the ITER vacuum vessel will produce a magnetic field whose primary function is to confine the plasma particles. The toroidal field coils are designed to produce a maximum magnetic field of 11.8 tesla and store 41 gigajoules of energy. Weighing 360 tonnes each, and measuring 9 x 17 m, they are among the largest components of the ITER machine.

The technical specifications of the coils were transferred by the ITER Organization to the procuring Domestic Agencies through Procurement Arrangements in 2008. Since then, ITER Japan (nine toroidal field coils plus all coil cases) and Europe's Fusion for Energy (ten toroidal field coils) have selected industrial suppliers, completed design and manufacturing qualification activities for each fabrication step, and launched series production. What begins at the factories will be continued at ITER as—by pair—the toroidal field coils are interlinked with one vacuum vessel sector and vacuum vessel thermal shielding before taking their place in the tokamak assembly pit. All toroidal field coils are expected at ITER by 2022.

Because the precision of coil geometry is critical to creating the magnetic field required for plasma confinement, any non-conformity of fabrication tolerances or assembly misalignments can result in errors in magnetic configuration. As a result, particular attention has been paid to dimensional control throughout the fabrication process—from the manufacturing of the core winding pack and case structures, to the insertion of the winding pack inside of the case, and finally closure welding and final machining.

Factory acceptance tests were completed on the magnet on 19 January 2020 with the participation of ITER Organization observers. Electrical tests, dimensional inspection, visual inspection and pressure drop measurements confirmed that the coil meets all technical specifications. The component will now be packed for international shipment.