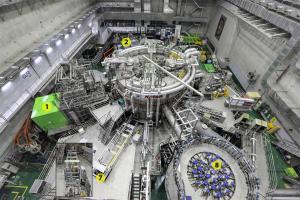

Image of the week

A closer look at KSTAR

10 Feb 2020

Over its twelve years of operation, the KSTAR tokamak (for Korea Superconducting Tokamak Advanced Research) has built an extremely valuable database for the future operation of ITER as well as for the design basis of a next-step DEMO machine.

KSTAR is considerably smaller than ITER (with a 1.8-metre major radius as compared to 6.2 metres) and it differs in many design details. The machine achieved high-performance operation mode (H-mode) in 2010 and reached an ion temperature of 100 million °C in 2018. KSTAR has proved especially efficient in suppressing edge localized modes (ELMs), a phenomenon that can occur during H-mode during which bursts of energy and particles are expelled from the plasma.

Along with the European JET, KSTAR has been at the core of an extensive international program to validate the design of an effective disruption mitigation system based on shattered pellets injection—the very system that will be installed in ITER.

A view from the back, looking toward the entrance. One of the shattered pellet injectors that were installed in 2019 is visible in the inserted image.

Let's take a guided tour of the pristine KSTAR hall at the National Fusion Research Institute in Daejeon, Korea.

1-2: Neutral beam injectors #1 and #2

KSTAR is presently equipped with two 110 kV positive-ion-based neutral beam injectors. A third is optional.

KSTAR is presently equipped with two 110 kV positive-ion-based neutral beam injectors. A third is optional.

3: Power sources

Whereas the power source for neutral beam injector #1 is located in an adjacent building, the three modules of the power source for injector #2 are installed in the KSTAR hall proper.

Whereas the power source for neutral beam injector #1 is located in an adjacent building, the three modules of the power source for injector #2 are installed in the KSTAR hall proper.

4: ECEI diagnostics system

The electron cyclotron emission imaging (ECEI) diagnostic is designed to visualize the electron temperature profile and fluctuations in 2D and 3D. In case a third neutral beam injector is installed, the system would be relocated.

The electron cyclotron emission imaging (ECEI) diagnostic is designed to visualize the electron temperature profile and fluctuations in 2D and 3D. In case a third neutral beam injector is installed, the system would be relocated.

6: Vacuum UV diagnostics system

This prototype vacuum ultraviolet diagnostics system uses spectroscopy to monitor transport and accumulation of the tungsten particles in the plasma.

This prototype vacuum ultraviolet diagnostics system uses spectroscopy to monitor transport and accumulation of the tungsten particles in the plasma.

7: Pellet injector

Part of the international program of R&D on ITER disruption mitigation, two shattered pellet injectors were installed in 2019 (one is visible in the inserted image, the other is in a diametrically opposed location).The equipment was provided by US ITER through Oak Ridge National Laboratory.

Part of the international program of R&D on ITER disruption mitigation, two shattered pellet injectors were installed in 2019 (one is visible in the inserted image, the other is in a diametrically opposed location).The equipment was provided by US ITER through Oak Ridge National Laboratory.

8: Cryovalves box

Connected to the cryoplant outside the hall, the valves are activated to control the flux of supercritical helium circulating in the magnet system.

Connected to the cryoplant outside the hall, the valves are activated to control the flux of supercritical helium circulating in the magnet system.