Assembly preparation

Off goes the lid

9 Apr 2020

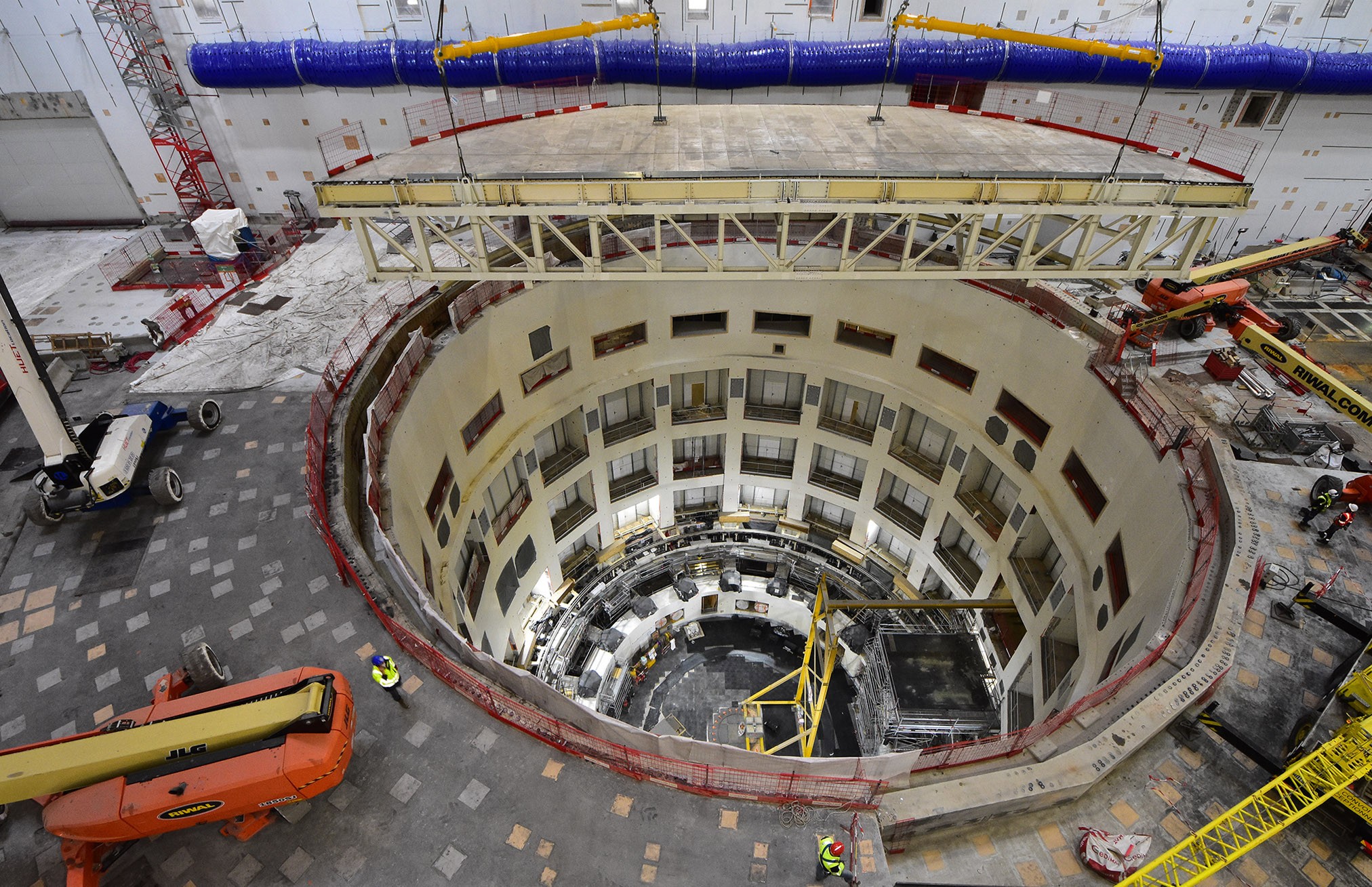

In the summer of 2017, a circular platform was installed inside of the large steel-and-concrete cylinder of the Tokamak pit. The 200-tonne structure was meant to protect the workers active in the lower levels while providing storage for activities above. The following year, the platform was hoisted some 20 metres to form a temporary roof, where it remained for two years. And finally, last week, the time had come to remove the massive "lid" to allow access to the pit in anticipation of the machine assembly phase. In two days, the 11 segments of the structure were dismantled, lifted and safely stored to be re-used at a later stage of ITER operations.

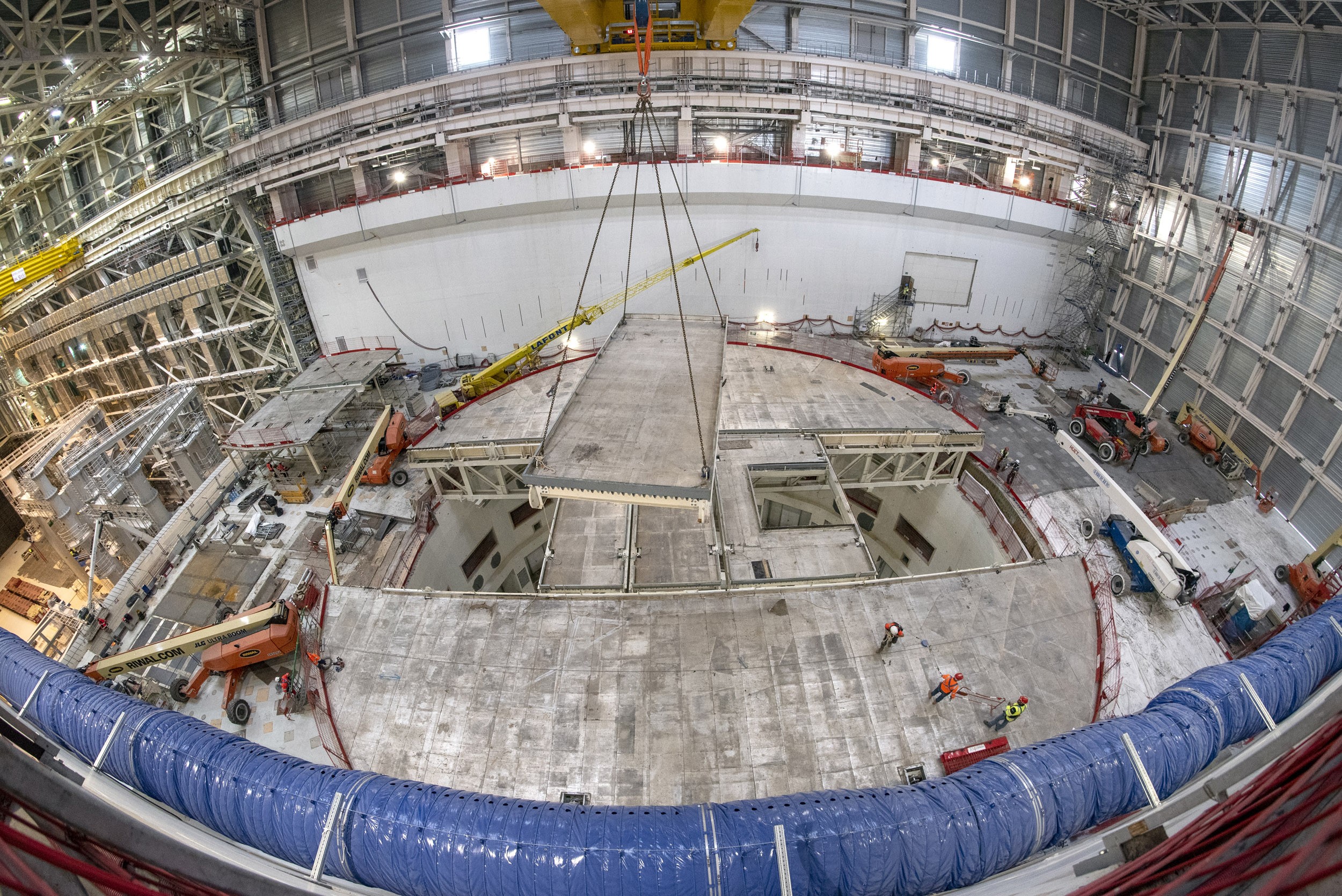

One of the smaller lid segments is being readied for lifting. In two days, the 11 segments of the structure were dismantled, lifted and safely stored to be re-used at a later stage of ITER operations

In the vast open space of the assembly theatre the powerful overhead cranes were back at work, lifting the lid's segments one by one, transporting them from one hall to the other, and delicately depositing them on the vehicles that would take them to storage—a regular flat-bed trailer for the smaller segments (10 to 20 tonnes), a dedicated self-propelled modular transporter for the two "half moons" weighing close to 80 tonnes each (more details in the image gallery below).

On its way to the self-propelled transport trailer, an 80-tonne half-moon segment passes over the upending tool.

The intense activity in the crane hall, with several elevated platforms moving painters along the rafters just below the crane runway, plus space limitations in the adjacent assembly hall where the upending tool was being prepared for another set of tests, added constraints to the already challenging operation.

But the well-oiled team, once again, proved up to the task. Access to the Tokamak pit is now open to the overhead cranes.