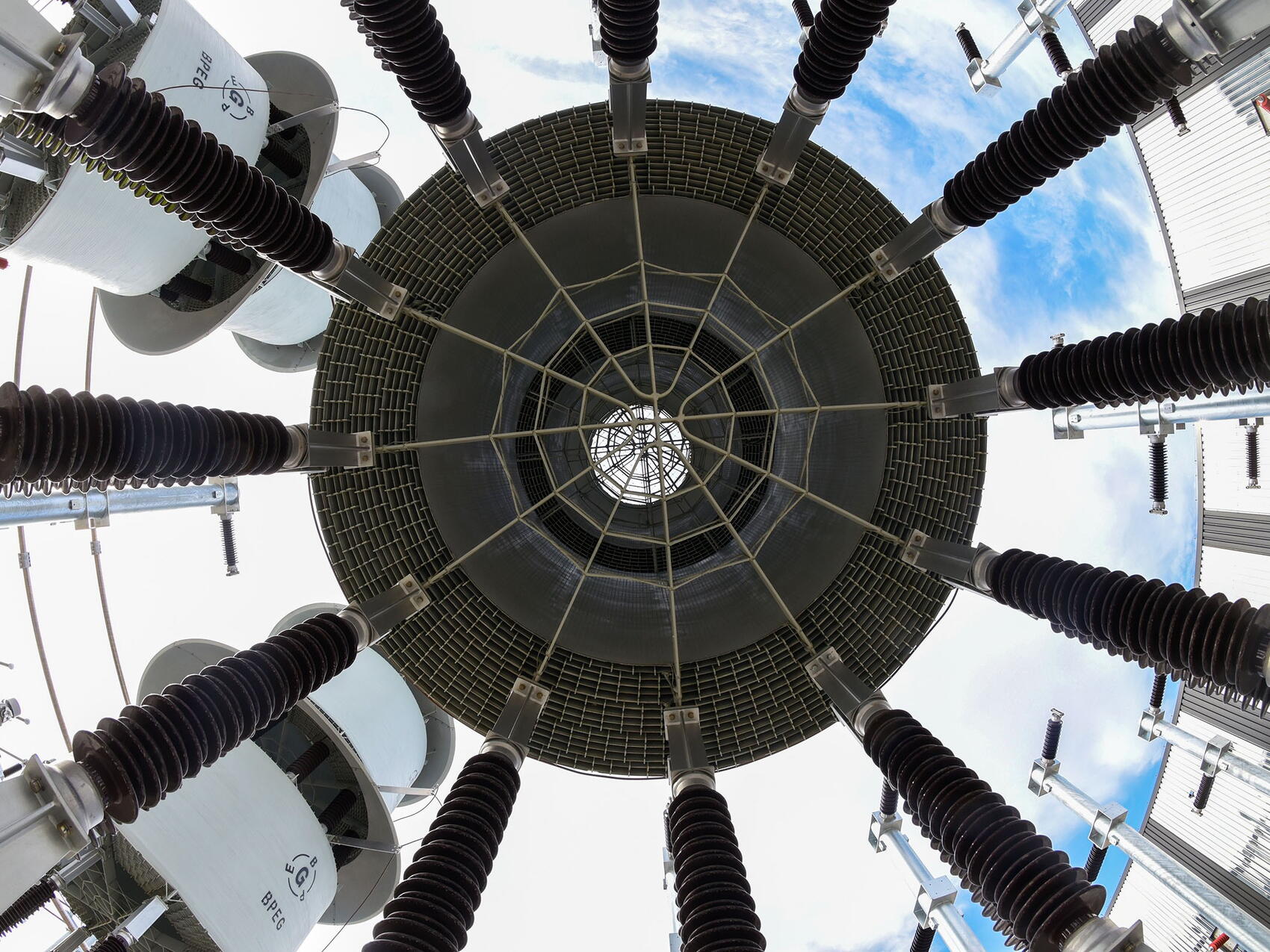

In most heavy industry zones, such as steelworks or shipyards, the equipment for "reducing the harmonic distortion" in the AC current fits into a medium-size building. In ITER, which requires up to 500 MW of DC power, it occupies not only a building—the Reactive Power Control Building—but also the adjacent one-hectare "reactive power compensators area."

What happens within this dense arrangement of thyristor-controlled valves*, reactors, capacitors, resistors and sensors is a complex process aimed at smoothing the flow of AC current both inside the ITER installation and in the immediate vicinity—namely the neighboring CEA-Cadarache research centre and the villages closest to the ITER site.

The process is about compensating the "reactive power" that is generated in the AC current by the presence of "charges," such as the AC/DC converters in the ITER Magnet Power Conversion Buildings.

Contrary to "active power," which lights lamps and operates machines, this ghost-like current does not perform any useful work—it simply moves back and forth within the AC flow.

Any AC/DC conversion installation tends to intensify the reactive power in the AC network and to create harmonic distortions in the sine wave. Because the equipment inside the

ITER Magnet Power Conversion Buildings is exceptionally powerful, the distortions, if not compensated, would deeply affect the local distribution of AC current.

It could also be quite costly in terms of electricity bills: transporting the useless reactive power has a cost, which the utility provider would end up billing the customer for. In this perspective, the construction of an efficient reactive power compensation system is a sound investment.

The ITER reactive power compensation and harmonic filtering system is among the largest in the world. In the Reactive Power Control Building, which hosts nine 3-metre-tall thyristors, equipment installation is now 80 percent complete; in the reactive power compensators area, it has passed the 75 percent mark.

Provided by China and manufactured by Rongxin Power Electronic Co. Ltd (RXPE), the equipment is being installed by the Italian Consortium Fincantieri SI and its partner SAET.

*Thyristors are powerful electronic switch controllers.