In-vessel coils

First components arrive on site

20 Oct 2020

-

Anna Encheva, ITER Magnet Division

ITER has received the first shipments of mineral-insulated conductor for ITER's in-vessel coils. The first lengths are destined for winding and bending trials as well as for the production of the first vertical stability coils on site.

The first spools of mineral-insulated conductor for ITER's in-vessel coils have arrived. All conductor lengths for the vertical stability coils will be delivered to ITER, while those destined for the manufacture of ELM coils and feedthroughs will be delivered directly to the supplier.

Produced by the Italian consortium ICAS S.r.l., the first four conductor lengths—each 105 metres long, on spools—have been transferred to a special temperature and humidity-controlled storage area on site.

Another two sets of straight conductor lengths (20 units, each 12 metres long) have been delivered to ITER contractor Vitzrotech, in South Korea, for the qualification and manufacturing of an auxiliary component called in-vessel coil feedthroughs.

Coming after nearly a decade of development and a detailed qualification phase to confirm the manufacturability of the final design, these deliveries represent a major milestone in the ITER in-vessel coil program.

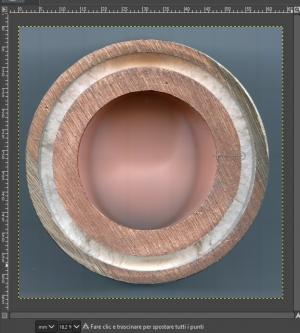

A cross section of in-vessel coil conductor, with a layer of magnesium oxide (MgO) insulation between the external stainless steel jacket and the high conductivity copper conductor (and cooling channel).

The mineral-insulated conductor has been specially developed for the in-vessel coils to withstand large transient electromagnetic fields, high radiation flux, and high temperature. The mineral layer—made of compressed magnesium oxide (MgO) powder—has three main functions: structural support of the copper conductor; thermal conduction between the stainless steel jacket and the copper conductor; and electrical insulation between the jacket and the conductor. The specific hydroscopic nature of this layer—as well as the final high stiffness of the conductor—must be taken into account in the development of winding and bending procedures for both types of in-vessel coils (vertical stability and ELM).

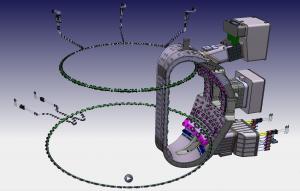

Two ring-shaped vertical stability coils will be mounted on rails close to the plasma—but behind the protection of the blanket modules—in order to provide a fast and efficient contribution to plasma control. Located at the top and bottom of the vessel, the coils differ slightly in diameter, but are built from the same type of mineral-insulated conductor.

Both coils are wound from four turns of conductor that are connected in series. The length of one turn varies: an upper vertical stability coil turn is roughly 35 metres; a lower vertical stability coil turn is about 47 metres, without feeders.

As part of risk reduction related to the insulation performance of the in-vessel coil conductors, an irradiation program has been developed and will be performed at Oak Ridge National Laboratory (US). An essential part of this program is to measure the breakdown voltage and resistance as a function of cumulated gamma irradiation dose.

A representation of upper and lower vertical stability coils installed in the vacuum vessel, with feeder lines and feedthroughs extending out through upper and lower ports.

Another challenge ahead is the manufacturing of in-vessel coil feedthroughs—ancillary components that are part of the feeders that deliver electrical power and cooling water to the coils, and which have particular requirements because they cross between the vacuum boundary and normal atmosphere. Feedthroughs are classified as protection- and safety-important components and, as such, have stringent requirements in terms of reliability, inspection, and capability to withstand accidental events such as plasma disruptions, seismic events, and power supply failures without the loss of their safety function.

Bending and winding trials for the vertical stability coils will start in 2021, as soon as the tender process is completed and the contract is awarded. The qualification of the feedthroughs will conclude by end of 2021, and the first batch of feedthroughs is expected in September 2022. Conductor manufacturing should continue through early 2023, when the last conductor lengths are delivered to the supplier of the ELM coils.

*The ICAS consortium is composed of ENEA, Frascati, Italy (general project management, scheduling, administration and quality assurance); Tratos Cavi S.p.A., Pieve Santo Stefano, Italy (cable manufacturing); and Criotec Impianti S.r.l., Chivasso, Italy (jacketing and the completion of the unit conductor lengths).