How to (carefully) transfer ITER's heaviest components

Functional tests on the "sector lifting tool" have demonstrated that the tool's controller and actuators are ready to implement operator commands during the delicate lifting operations of vacuum vessel sectors, toroidal field coils, and the finalized sector sub-assemblies.

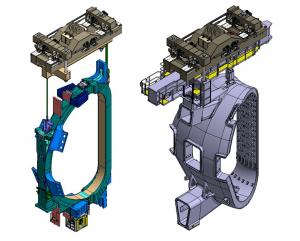

The sector lifting tool is a purpose-built assembly tool designed and manufactured by the Korean Domestic Agency to lift and transfer some of ITER's heaviest components—vacuum vessel sectors and D-shaped toroidal field coils—as well as the nine sector sub-assemblies that will be created on ITER's tallest assembly tools.

The overhead travelling cranes cannot "grasp" these major loads directly; instead, several layers of attachments intervene between the cranes and the components to be lifted.

First, a 90-tonne beam attached to the four hooks of the double crane provides a single connection for the next-layer of lifting attachment. This "dual crane heavy lifting beam," which allows the cranes to work in tandem and lift loads of up to 1,500 tonnes, has been procured (along with the cranes) by the European Domestic Agency. (It does not appear in the image below.)

For the components that must be mounted on the sector sub-assembly tool, the next in order is the sector lifting tool, which attaches to the dual crane heavy lifting beam through a pin connection.

The tool will interface at three points in two places with toroidal field coil lifting beam to lift the coils from the upending tool to the sector assembly tools. For the nine vacuum vessel sectors, the sector lift tool's direct interface will be the nine radial beams, which are part of the in-pit assembly tools. These radial beams are transported from the pit to connect to each sector in its upended (vertical) orientation, and they remain attached to the sector through transport (under the sector lifting tool) to the sub-assembly tool, throughout the sub-assembly operation, and through delivery and installation in the Tokamak pit.

Considering the importance of the centre of gravity when lifting such heavy loads, the sector lifting tool has been designed with a balancing control system that can be activated through controllers and electrically driven actuators. The tool is equipped to perform horizontal-plane adjustments along the X and Y axis (longitudinal and transverse) in order to balance the loads before the lift. This system, which was first confirmed during testing at ITER Korea, has been verified through functional site tests this month at ITER.

Early next year, the fully tested sector lifting tool will enter into activity—playing an important role in transferring the first toroidal field coils and the first vacuum vessel sector to the standing tools in the Assembly Hall.