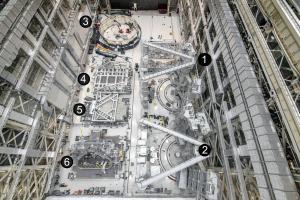

Captured from on high

3: The silver-plated lower cylinder thermal shield (20 metres in diameter, 50 tonnes) will fit inside the soup-dish-shaped depression of the cryostat base to form a heat barrier protecting the magnets at superconducting temperature. It will be inserted into the assembly pit near the end of the year.

4: The upending tool is tasked to handle the vacuum vessels sectors (440 tonnes) and toroidal field coils (360 tonnes). Once securely clamped into the massive steel structure, the components will be lifted, upended from horizontal to vertical in mid-air, unclamped and delivered into the arms of one of the SSAT tools for pre-assembly.

5: This steel structure is used to attach dummy loads to the upending tool. It is sitting on the pair of dummy loads that were used for testing the sector sub-assembly tools and the overhead crane load path.

6: Delivered to ITER on 7 August, vacuum vessel sector #6 is undergoing a number of installation activities prior to pre-assembly operations next year. The welding of approximately 800 diagnostic bosses has been finalized; now it is the turn of small studs and clips.