Test facility confirms remote handling approach

The extremely challenging remote maintenance operations planned for ITER require that engineers and system owners plan and rehearse for them now. In the latest set of trials run for ITER at the UK Atomic Energy Authority's RACE facility, teams successfully demonstrated the remote handling replacement of ITER's test blanket modules that will be performed in the ITER Hot Cell.

As a first-of-a-kind fusion reactor, ITER will be facing a number of unprecedented challenges in the remote handling and maintenance of novel, multi-tonne components in hostile environments with little or no direct viewing.

A partnership between the ITER Organization and RACE (Remote Applications in Challenging Environments) is helping the ITER remote handling team and systems owners to test whether component designs are well matched with the maintenance capabilities of the project before the manufacturing process is initiated, so that costly rework at a later date can be avoided.

"We think of RACE as our off-site mockup facility," says remote handling engineer David Hamilton. "Carrying out a task through remote handling is necessarily more clumsy and crude than if it were carried out by hand. We need to ensure that the designs of the components have suitable features, and that the remote handling job can be done; for this, there is nothing better than practicing with a full-scale mockup in conditions similar to what we are expecting."

RACE has already concluded a task on the maintainability of the ITER equatorial diagnostic port plugs and implementing agreements are underway relating to the remote maintenance of the vacuum vessel pressure suppression system, the feasibility of cutting and welding diagnostic first wall cooling pipes, the remote handling of vacuum flanges, synthetic viewing, and the precise tensioning of bolts by robotic tools.

In late November/early December, the RACE team held final mockup trials demonstrating the remote handling replacement of ITER test blanket modules.

Two of ITER's equatorial (mid-plane) port plugs will host tritium breeding blanket mockups called test blanket modules (TBMs). The modules are drawer-like structures situated at the plasma end of the port plugs, and each plug will host two. The remote handling replacement of the TBM sets is scheduled during every long-term maintenance period during fusion operation at ITER, or approximately every two years, making the TBM port plugs Remote Handling Class 1 components.

"A lot of R&D has gone into this replacement operation to ensure that it can be done regularly and reliably," says mechanical responsible officer Byoung Yoon Kim from the Tritium Breeding Blanket Section. "With RACE, we're getting to see our ideas in action."

To carry out the mockup trials, the RACE team designed and built the mockups of a TBM set and of a TBM frame according to ITER specifications—a process that has already generated valuable feedback about component design. These mockups faithfully reproduce the size and weight of the actual components, their centre of gravity, and all interfacing features and tolerances.

An external guiding system—the solution for ensuring that the TBM sets can be inserted without touching the sides of the port plugs along a trajectory of more than 2 metres from the back of the port plug to the front—is also an important part of the demonstration of remote handling feasibility.

"When it's time to refurbish the ITER test blanket modules, the TBM port plugs will be removed from the machine during maintenance and delivered (in a horizontal position) to the ITER Hot Cell Facility. In the Hot Cell, they will be raised to vertical for the TBM set replacement activity," says Kim. "At RACE, we are testing the tools and the protocol of this highly precise replacement operation with full-scale physical mockups. It's invaluable."

Over two weeks, the ITER team witnessed the TBM port plug mockup demonstration trials by video conference and live stream. "This is the first of the RACE trials that we have not been able to witness in person because of the Covid-related restrictions," regrets Hamilton. "It's not ideal, but we are all making the best of it."

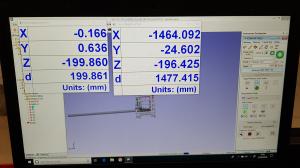

The first two days were dedicated to the critical remote handling operation, with particular attention to the precision of the guiding system. The detailed processes and results of the trial are summarized as follows:

- the 3-tonne guiding system (height of about 3 metres) was successfully positioned and fixed with the flange of the TBM set mockup (8 tonnes);

- the guiding system with the TBM set mockup (with a total weight of 11 tonnes) was successfully lifted and positioned into the four holes of TBM frame mockup;

- the lowering of the TBM set mockup was successfully carried out with sub-millimetre precision over more than 2 metres.

A number of auxiliary tasks were performed, such as the replacement of the vacuum seal, the positioning of cover plates, the bolting of the TBM set flange, the leak testing of the vacuum seal, and post inspection after dismantling.

"Useful suggestions have been made throughout the process, including the definition of requirements phase, the design phase for the mockups and tools, fabrication and testing," says Kim. "These suggestions relating to the remote handling compatibility of the component designs will be incorporated as we move forward for the final design of TBM port plug."

"The feedback from these trials drives improvements both to the remote maintainability of the component and the Hot Cell remote handling tooling," adds Hamilton. "The mockup structures will later be transferred to the ITER on-site mockup facilities where they can be used for ongoing trials and training of personnel using the actual remote handling equipment and tools."