Strong base for a very heavy task

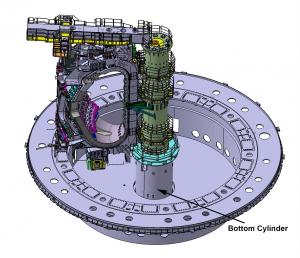

The two operations are related. The vertical sector will now be transported a few metres and installed on one of the V-shaped assembly tools, where it will be "sub-assembled" with two vertical coils and panels of thermal shielding. The resulting "vacuum vessel sub-assembly," weighing 1,200 tonnes, will then be moved into the pit, where the in-pit column tool will be waiting, ready to support, align, and stabilize the vacuum vessel sub-assemblies as they are joined and welded.

Each vacuum vessel sector will be supported by a radial beam that shares its load between the central column on one side and the concrete bioshield on the other through brackets embedded in the bioshield wall.