Another faultless sequence

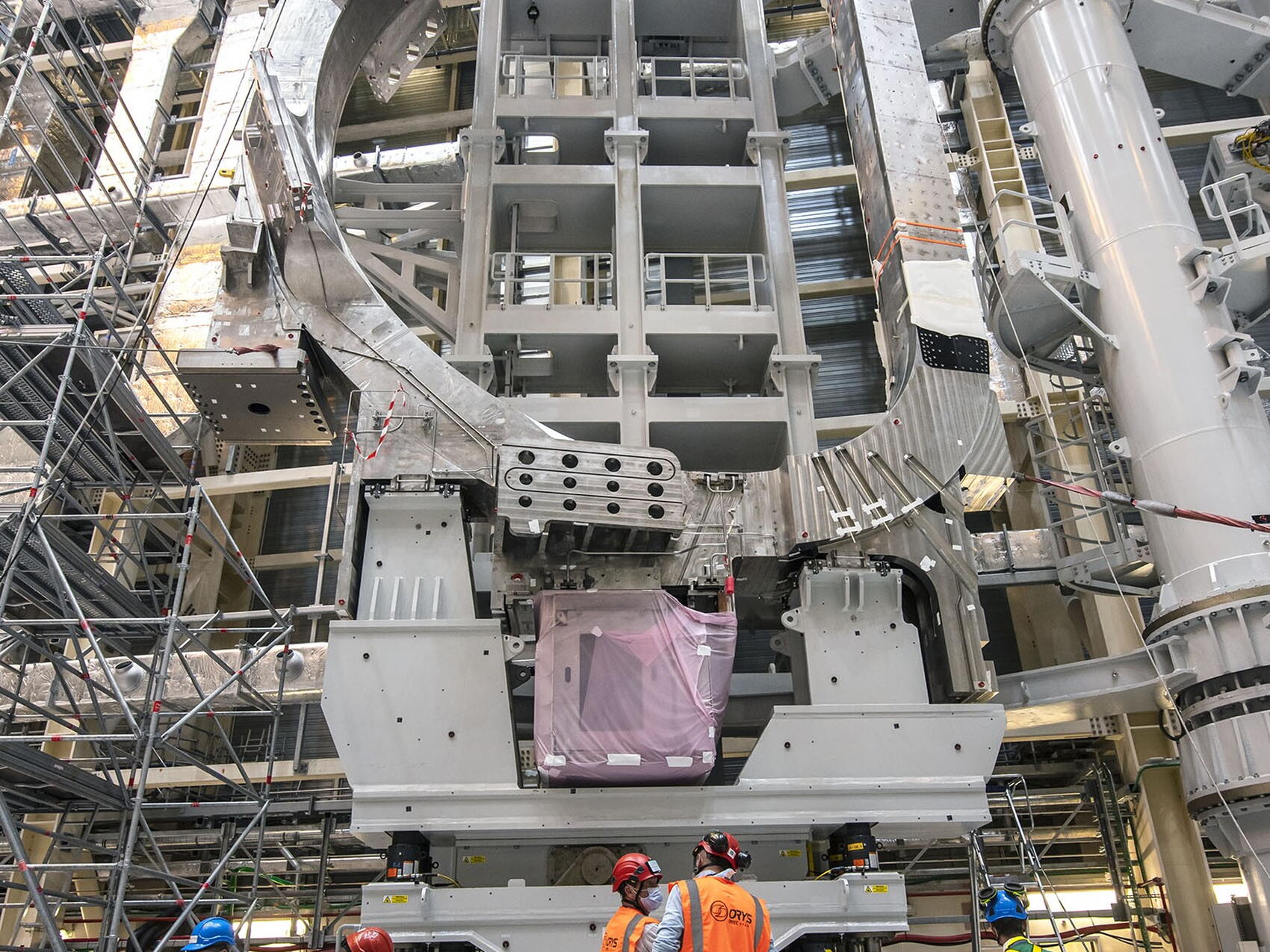

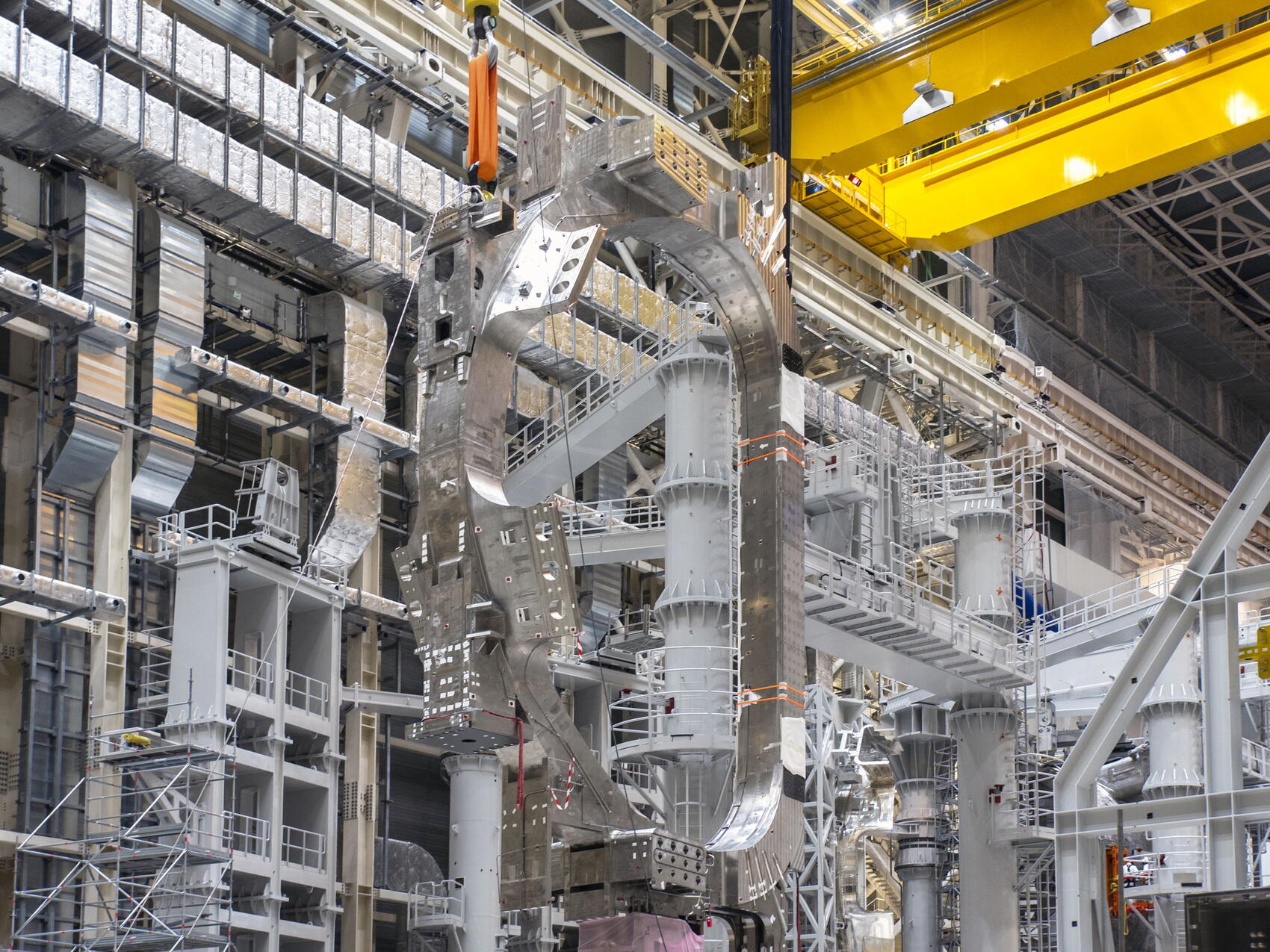

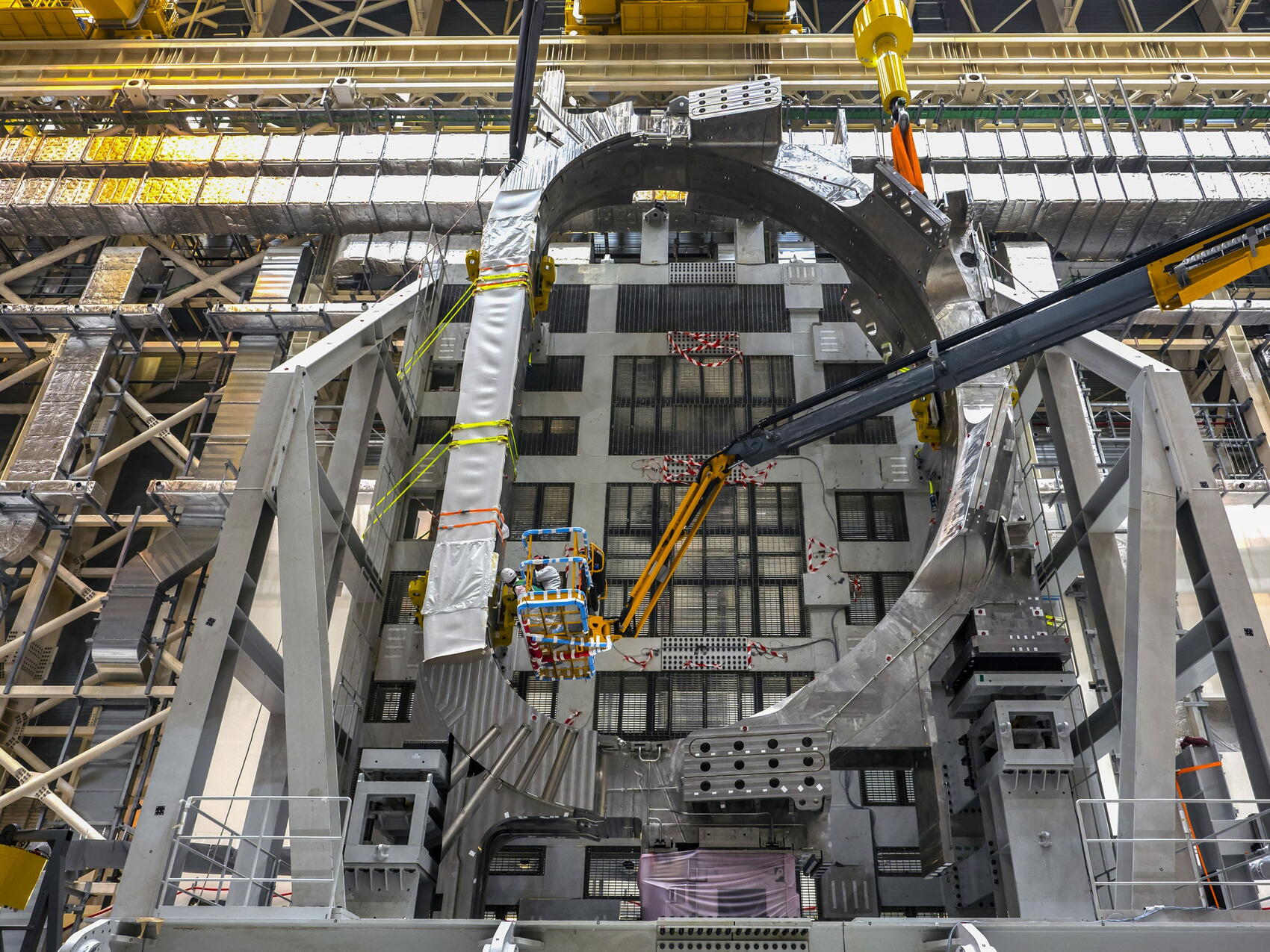

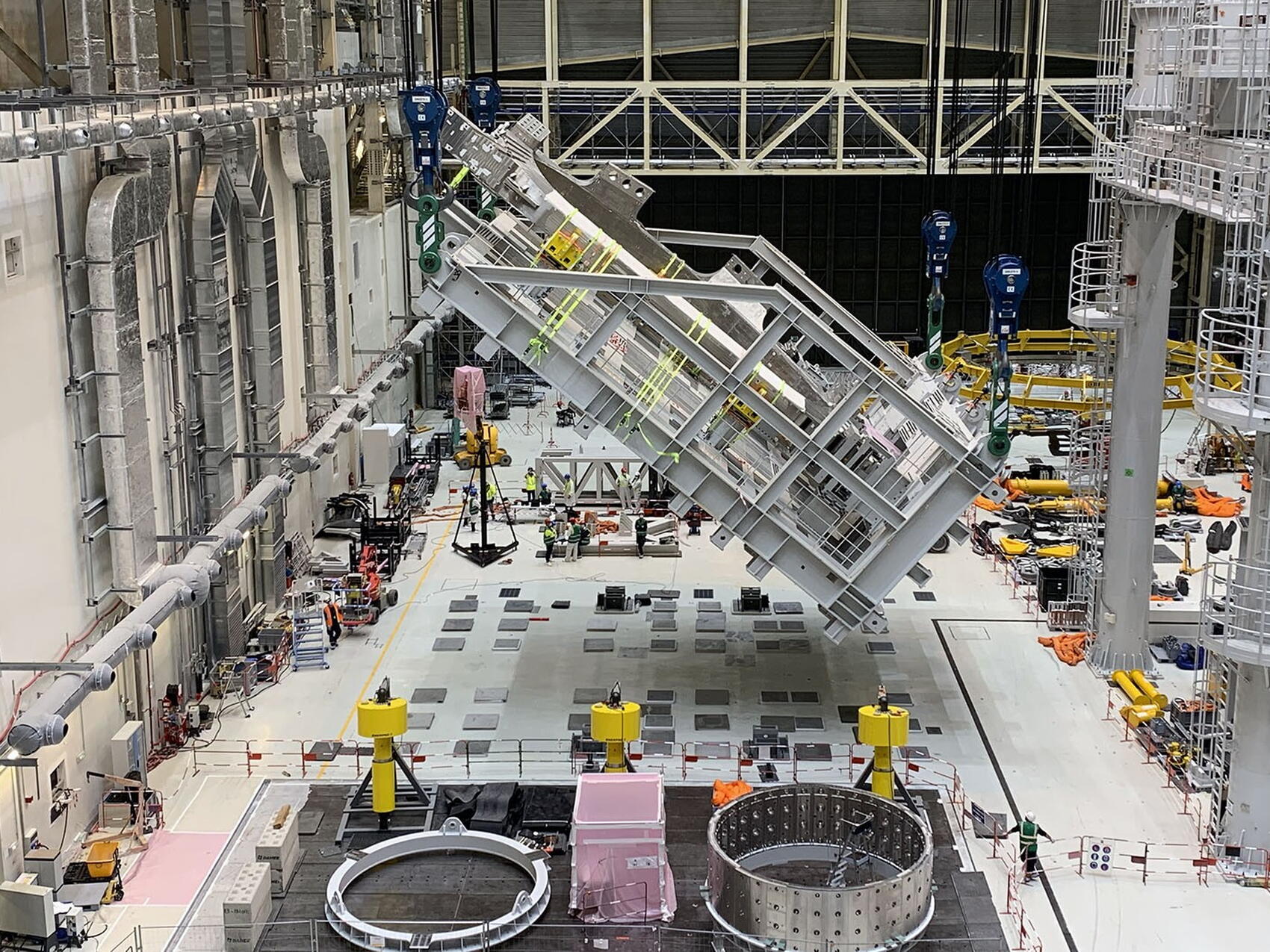

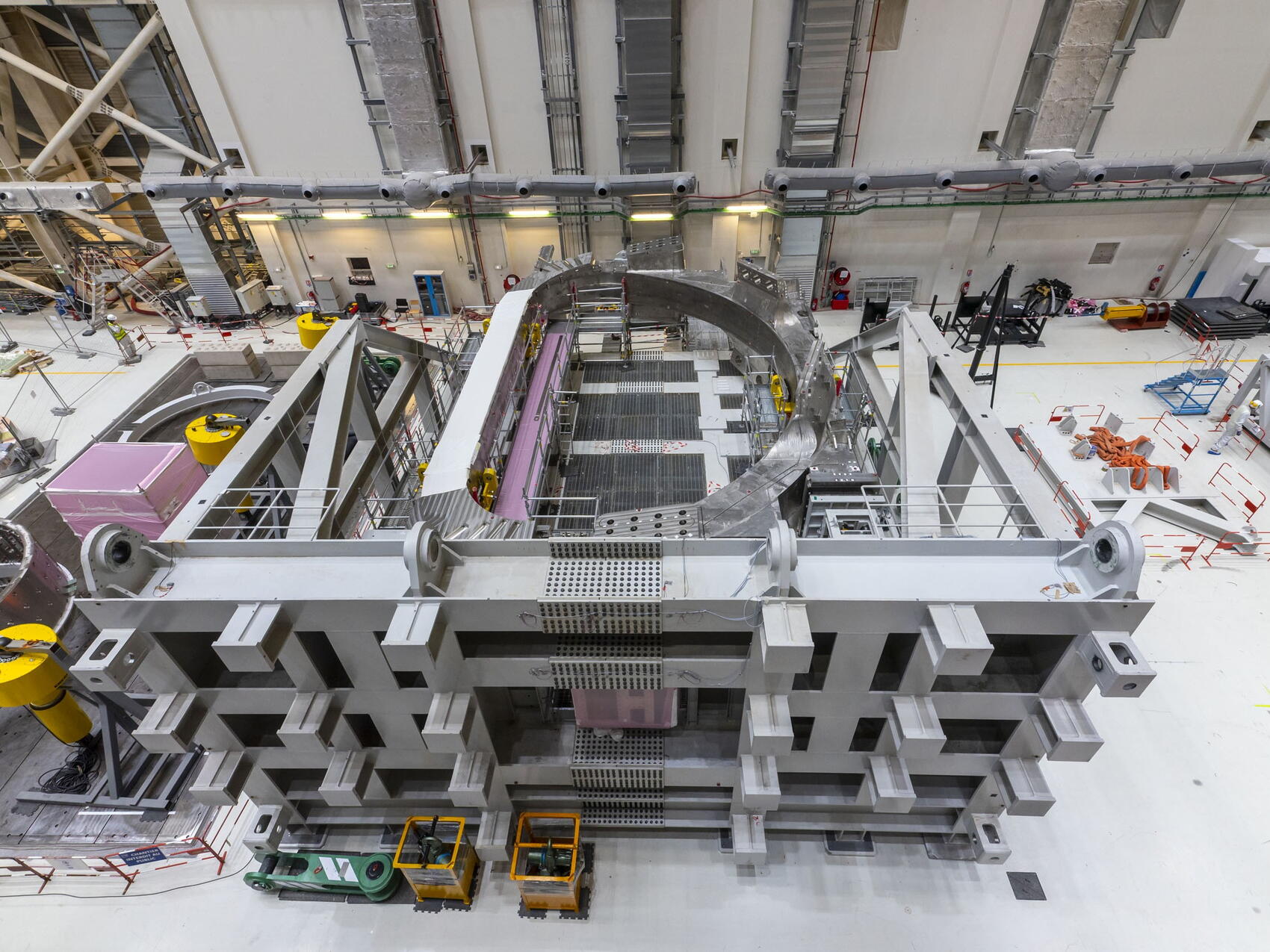

Finalized by Japan in January 2020, delivered to ITER two months later, toroidal field coil #12 (TF12) has moved yet another step closer to its final installation inside the assembly pit as part of the first "pre-assembly" of the ITER machine. In a series of operations that started on Wednesday 9 June and concluded six days later, the 320-tonne component, securely fastened to the upending tool, was successively tilted 90° in mid-air, re-positioned vertically on the floor, extracted from its massive steel cradle, and eventually attached to the left wing of one the twin sector sub-assembly tools (SSAT-1).

The component will remain in this position for about a month, before it is moved to the other sector sub-assembly tool (SSAT-2) for the actual pre-assembly operations. There are several reasons for this temporary stopover: available space in the Assembly Hall is scarce, the upending tool will soon be needed for TF13 (TF12's "partner" in the first pre-assembly), and the complexity of installing a one-of-a-kind component in a one-of-a-kind tool called for rehearsal in actual conditions. "In a way, it was a kind of training," said Head of the ITER Sector Modules Delivery & Assembly Division Chang Ho Choi on Tuesday afternoon as the operation came to a close.

Although it was "a bit longer than anticipated," the operation was "quite successful, with no show-stopper, no physical mismatching, and no major adjustments required. It all went very smoothly," confirms Chang Ho.

What took time and required almost a full day of delicate tweaking was the "balancing" of the load, once it was detached from the upending tool. Although the whole sequence had been practiced with a dummy load whose weight and general shape was representative of a D-shaped 320-tonne toroidal coil, and although models and calculations had determined the coil's theoretical gravity centre, balancing the load was to prove a long and painstaking process.

By Tuesday 15 June, six days after operations started, TF12 travelled safely into the left wing of tool #1. In two weeks, TF13 (also from Japan) will be placed in the upending tool to later follow the same sequence of operations, this time directly into SSAT-2.

Lessons learned in the present operation will prove priceless. In the course of machine assembly, this very sequence will need to be performed 18 times.